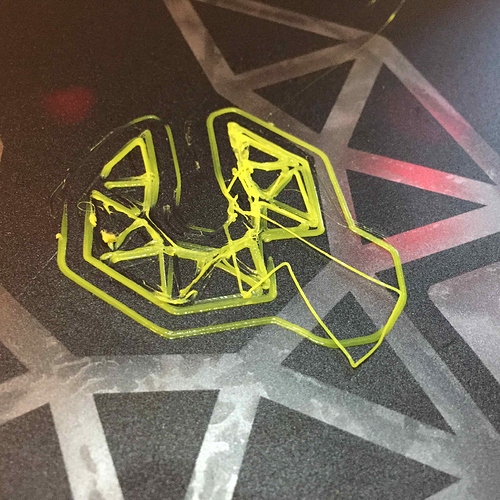

The printer started having trouble with first layer adhesion. I could sometimes get it to stick, but the majority of prints would fail.

I also noticed a black residue building up on the smooth rods from bushing break-in. I was oiling the bushings and wiping the rods down before every print. The instructions mention that the bushings need time to wear in. I came to suspect that the bushings had too much friction during rapid print head movements, which would sometimes dislodge a magnetic coupler, and other times cause a belt to skip a tooth.

I continued running prints and cleaning the rods, but I grew impatient because of the high failure rate. I considered using brass polish or some other mild abrasive to speed up the break-in process, but decided this would be detrimental to the machine over the long run.

At this point, I decided to short-circuit the tedium of wear-in. I replaced the brass bushings with six LM10UU linear bearings, as documented in another post. This appears to have resolved any remaining issues I was having with thrown magnets, skipped belts, and even, surprisingly, calibration/first layer adhesion.

I am still working through the full ramifications of this modification, but it validates that the Delta is capable of excellent performance once the bushings are properly worn in, so be patient with yours, keep the rods clean, and wipe away the excess oil until you can get a few dozen prints through it.