I have had a Delta for less than a week. Like others here, I’ve had some challenges getting the printer to work reliably. At some times everything would work great, then it would suddenly stop getting good first layer adhesion, or the belts would start skipping teeth. So I was tinkering with it when I saw a comment from Velleman about letting the brass bushings break in “like a new engine.”

I have been applying “3-in-1” oil to the bushings and wiping away the black sludgy residue from the vertical rods. I could tell that the bushings were not sliding quite as smoothly as they should.

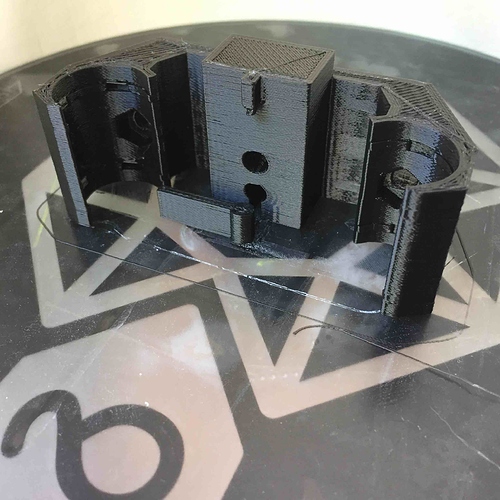

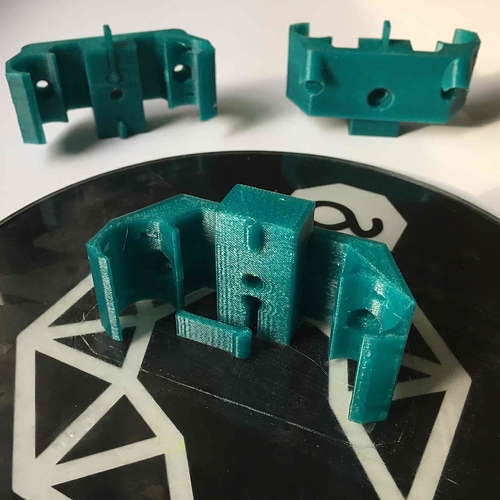

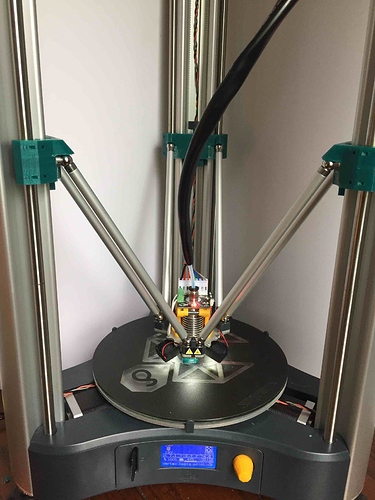

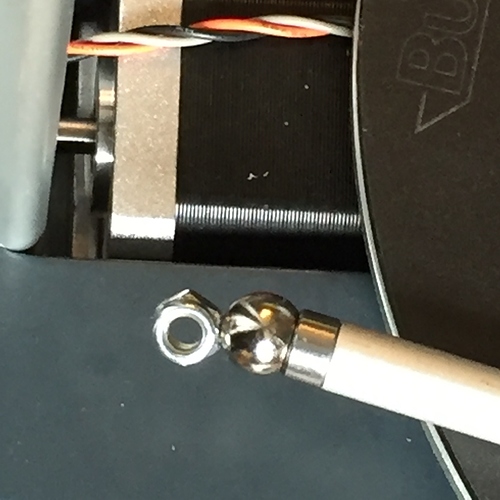

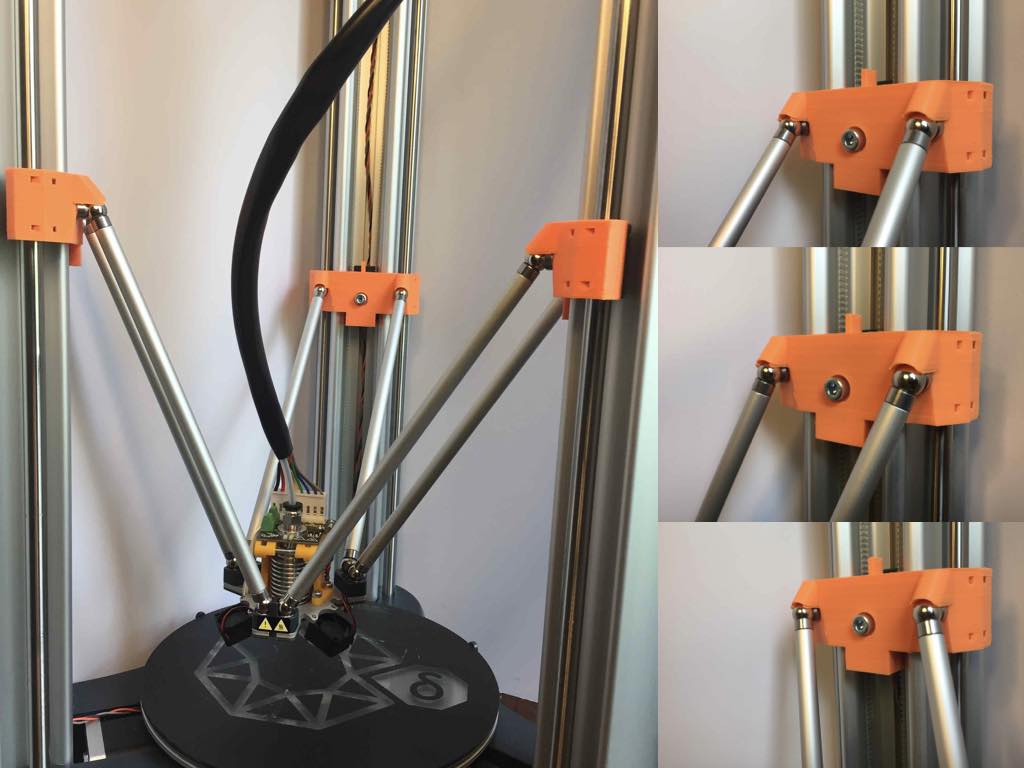

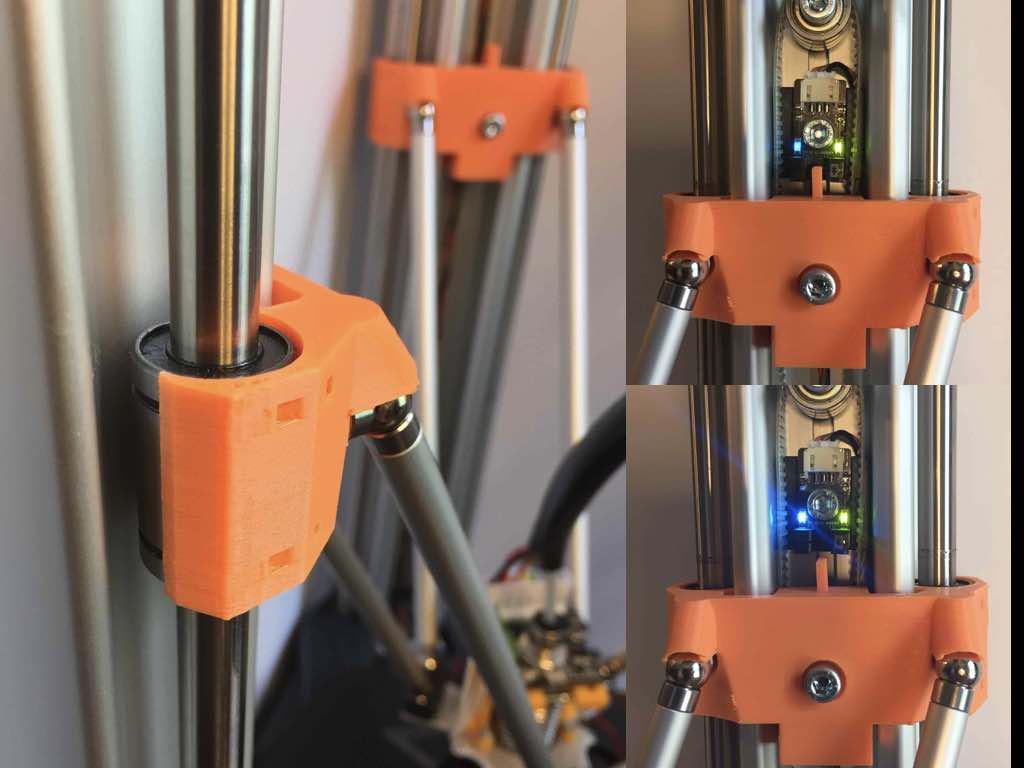

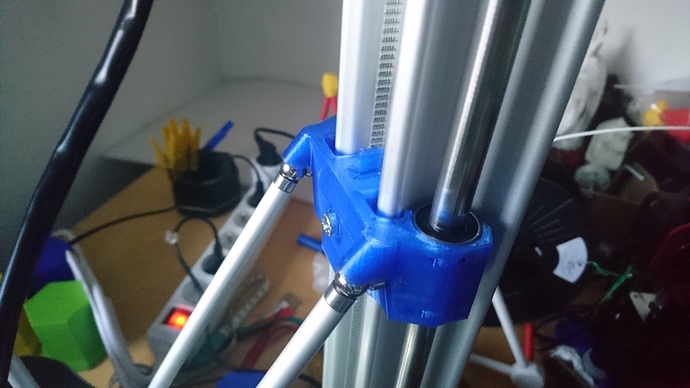

I considered using some brass polish to try to help the bushings break in more quickly, but instead settled on a different solution. I replaced the brass bushings with LM10UU linear bearings. (These are used in the K8200 kit on the lower rods in the X-Y Table assembly.)

There were a few complications in doing this, but it was primarily a matter of removing the top plate from the printer and swapping them out. The initial results are promising. The printer is already noticeably better at getting a good first layer, which has resolved the skipping belts and thrown rod problems as well.

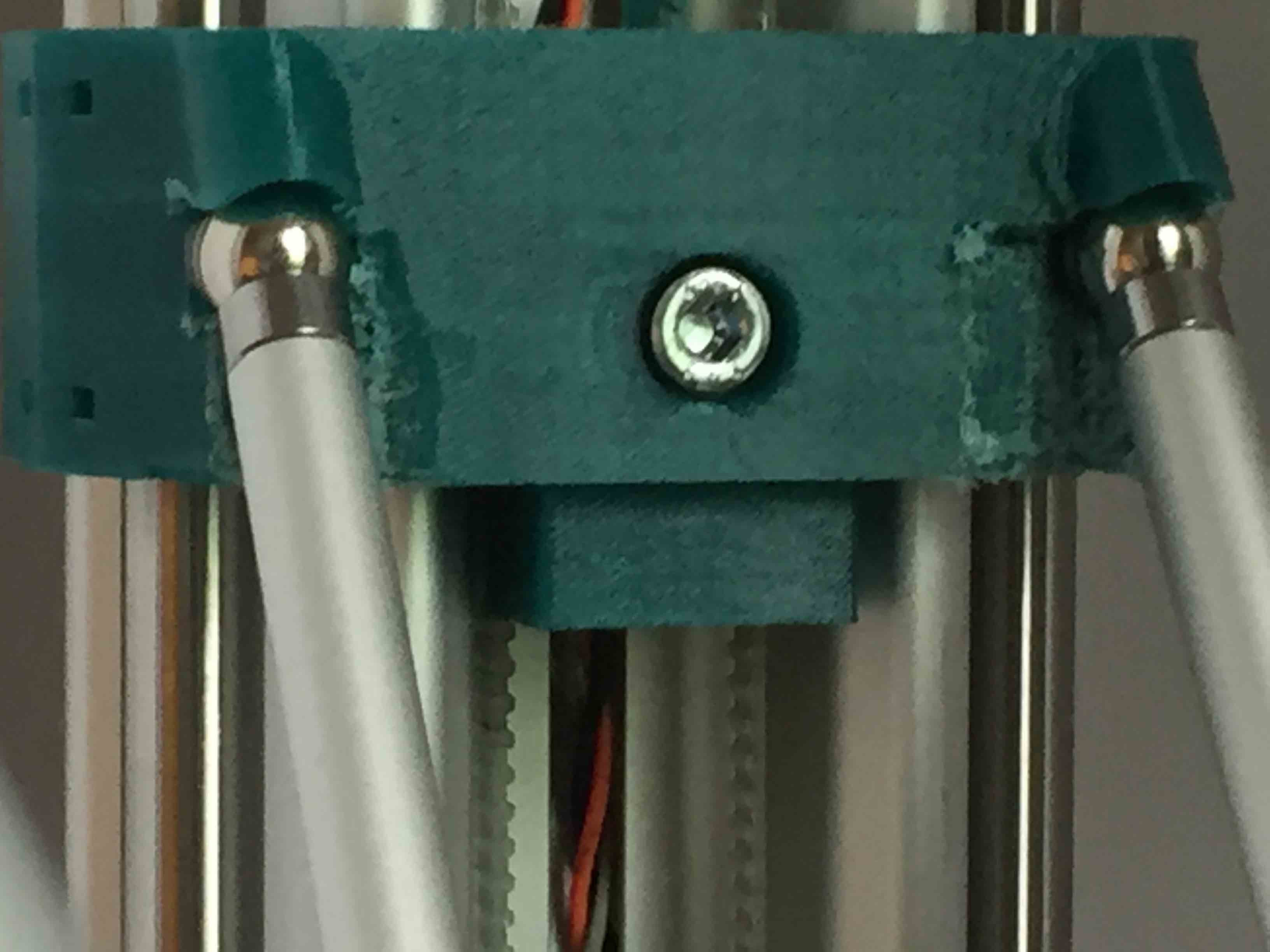

As you can see from the pictures, the LM10UU is not the same physical dimensions as the stock bushing. I was able to secure it to the sled with tie-wraps, but this also changed the geometry of the printer slightly.

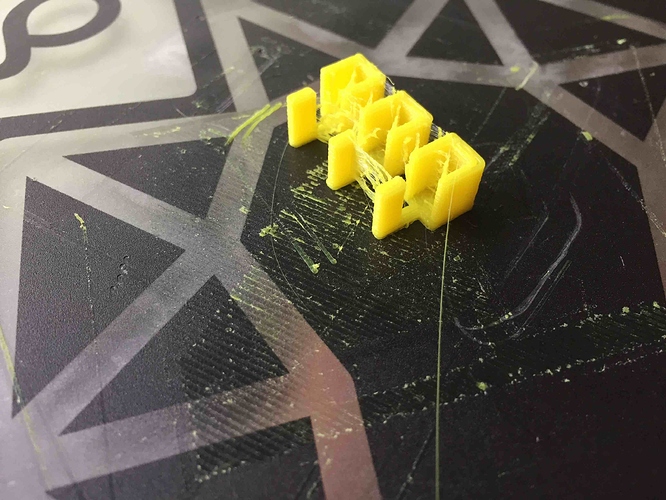

One consequence of this was that I needed to extend the limit switch actuator a few cm. At first I just used small pieces of black electrical tape, but then I printed some small tabs to do the job.

I did not bother to change the Marlin firmware to account for the geometry change, but it appears to be a simple change to one measurement in Configuration.h. I found that the printer was able to auto-calibrate and print without this change, though I suspect the dimensions will be slightly off until I correct the carriage offset value.

If you don’t want to go to all this trouble, my advice is to oil the brass bushings and wipe the rods clean before every few prints while the printer is breaking in, and be patient with it.