This is my third post on forum. My last post was

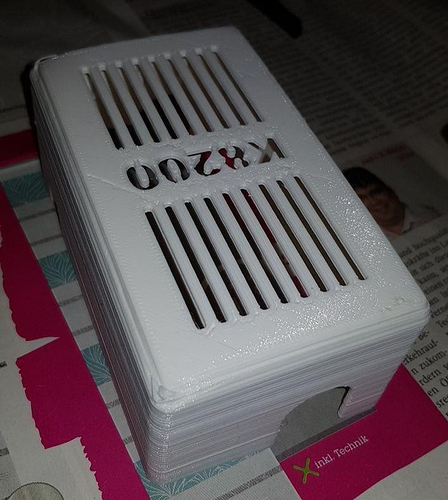

My very 1st print (the cover box of the K8200) was somewhat wavy in the Z dimension. I expected a smooth, even surface, but the surface was rather wavy:

So I took my time, installed the blender software, watched quite a few youtube videos, how to design a few 3d objects as well as prepare them for printing.

I wanted to design a couple of objects that could provide me different reference points along different dimensions. This includes:

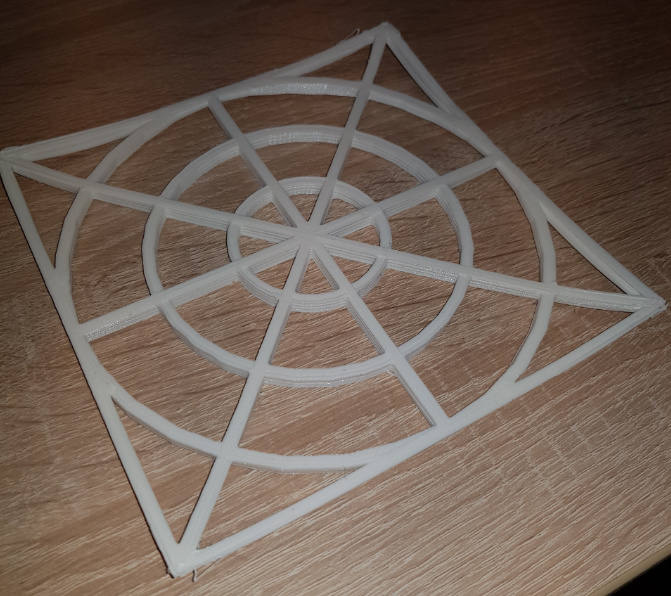

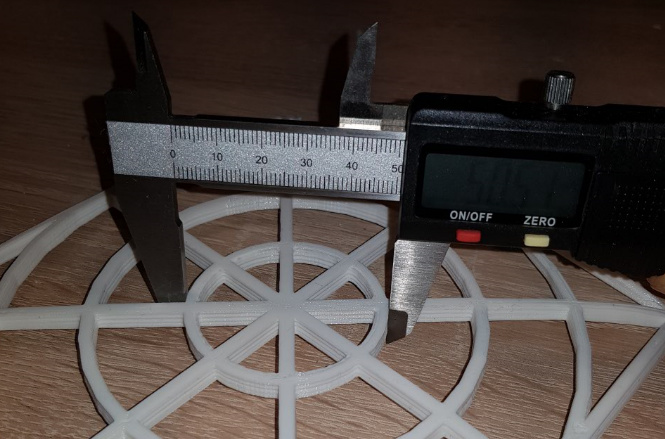

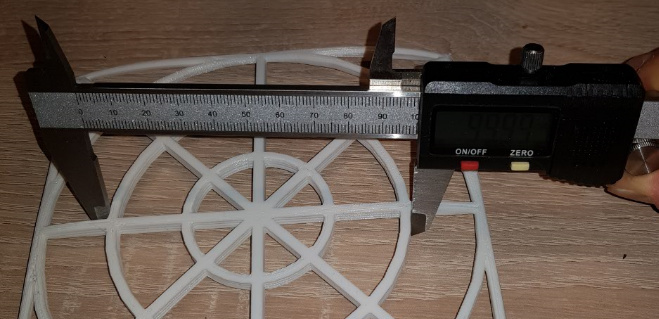

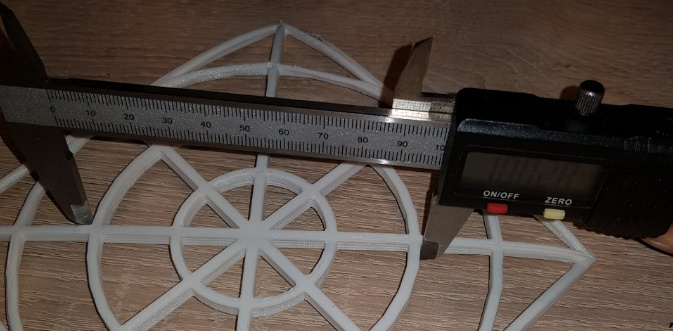

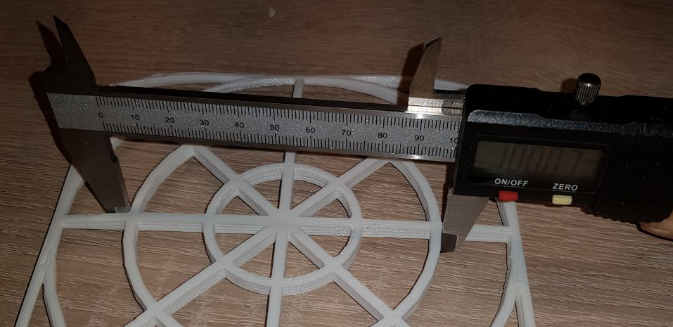

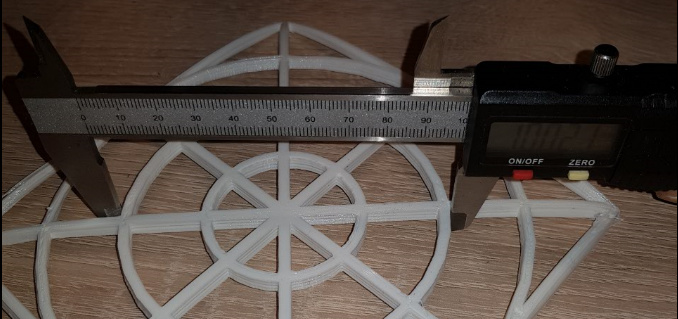

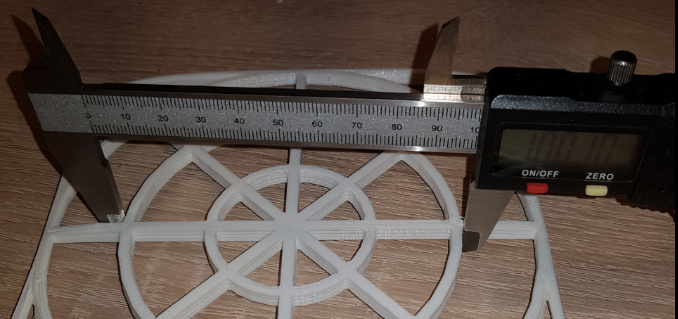

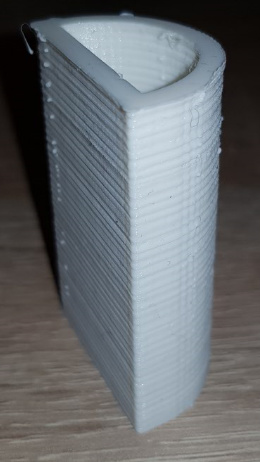

(1) an object of three-cycles-and five rectangles: 3C4R:

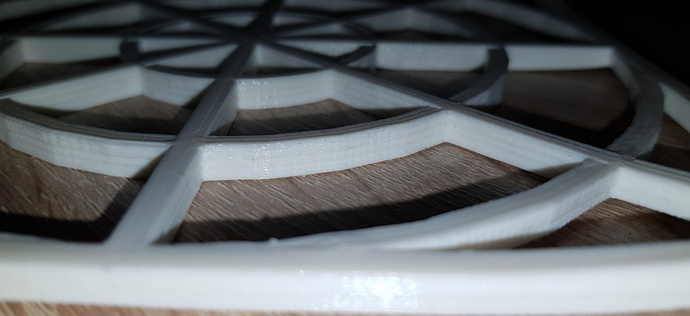

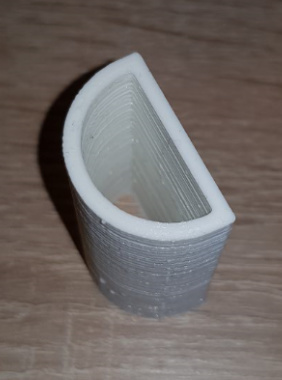

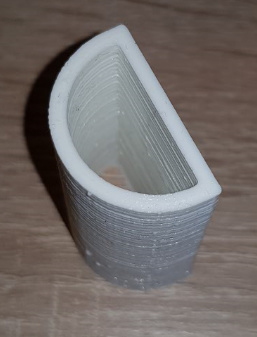

(2) a half cylinder 1/2C:

There are two apparent problems with the print:

- the surface is not even along Z dimension

- the edges of the print bent upwards as print progresses

The 3C4R was fixed to be manifold using some web site (suggested by k8200 software)

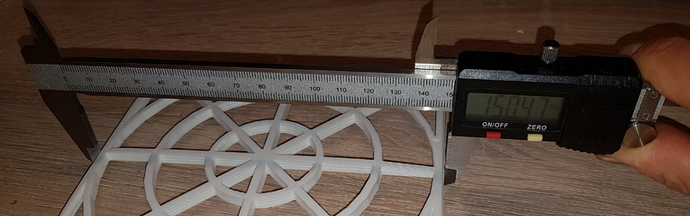

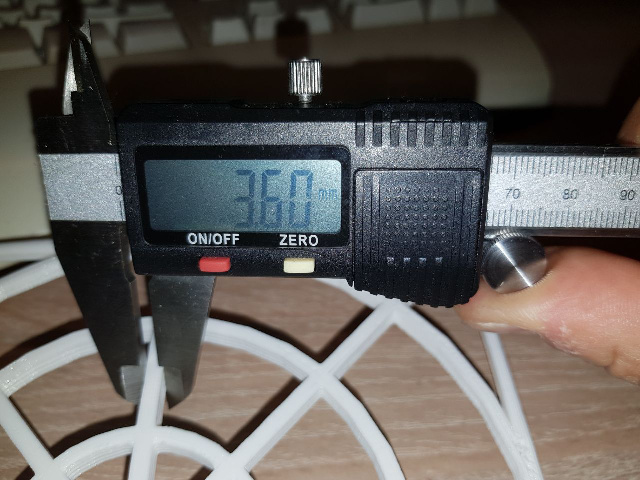

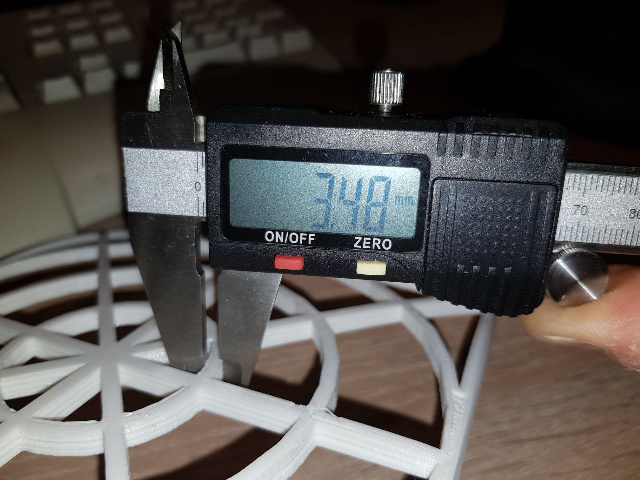

The circles of the 3C4R are of diameters 50mm, 100mm, 150mm and the print nicely approximates the sizes. The width of the edges of rectangles should be 3mm, but they vary substantially (always bigger than 3), usually 3.5 to 4mm:

It is five mm above the surface (+5 mm of along Z axis for the print)

and for the 1/2C (30mm wide, 50mm height):

The videos how the actual print took place are here:

3C4R: https://www.youtube.com/watch?v=XfiQ6Twm55c

1/2C: https://www.youtube.com/watch?v=0glDOzOlL8U&t=7s

The settings (printing and printer are as in PLA does not flow through extruder, if it does, flow is not uniform - #36 by arturas - K8200 3D Printer - Whadda forum - Community Help and Support)

I also have (at least must have) the screenshot video of the k8200 printing software while printing 3C4R. The PLA was at 190 degrees Celcius, and the bed was 50 degrees celcius.

The 1/2C print was different: the PLA was 190 degrees, but the bed was not able to keep up with the temperature (it dropped down to 45 degrees or so: why?) This infos could also be seen in the youtube video.

How can I adress these two problems?