Hi @Wrong_Way,

Thanks for your patience!

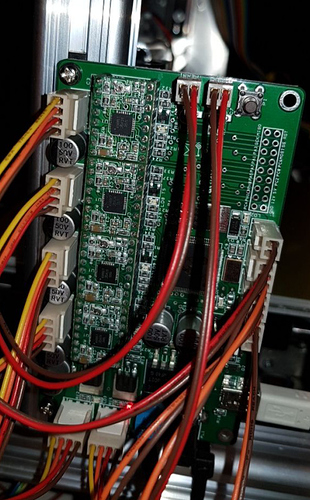

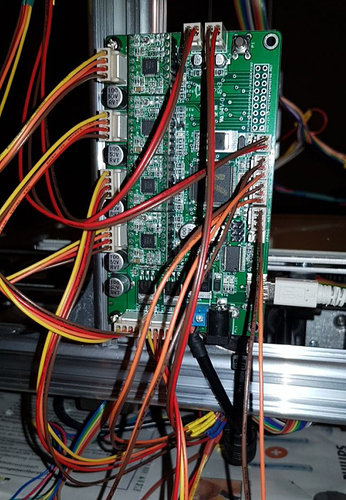

I’ve swaped the top 2 thingys (in you picture it is called A988/SP), I suppose that this is what you mean…

(w.r.t. the not stoppying on the Y axes: I take my words back. I am not able to reproduce that behaviou anymore)

Cheers,

Arturas

and I swapped the bottom two

there’s not a slightest change

I moved the Z axis now 1cm above the axies, and the PLA started moving down. That’s why I was so confused in my last reply (sligest change/nochange/there’s a change). Yuotube video to come.

It is already a minute or so, and the PLA is going down… Still…

And the PLA stopped moving down again. Maybe it was because I rotated the wheel with the had at the beginning?

another a fiew minutes passed.Unpatiently I moved the big cog with the hands a bit…to witness later, that the cog moves (quite a lot) itself counter-clockwise and then clockwise way. then the PLA was going out for a few minutes… and then the PLA stopped going out again.

I’m not sure what you mean.

You always want to extrude (clock wise) not retract.

If you retract to much it will pull it out of the tube.

Also you know the extruder will not start until the print head is over 270C this is a safety feature.

I think it is safe to ignore my last replay.

The current status: I let the sample print for an hour. Not that much came out.

I wonder whether there’s a sample, where one could say: in one hour, the big cog needs to turn X number of times (X% of the cycle)… Cause after an hour of printint the cog did not turn a lot…

Looking at your other pictures it looks like the screw with the spring is really tight.

Maybe you are putting to much tension on the PLA.

the bearing on the inside does it turn freely?

The large gear is it to tight maybe back the nut off a little.

Another thought,

When you assembled the extruder there were 2 screws that had to be filed down until they were level with the plastic part.

Did you do that?

Hi @Wrong_Way,

I knew that I forgot something! Do you have a picture of those two screws?

Cheers,

Arturas

Chapter 9 in the instructions.

Hi @Wrong_Way,

Thanks for the screenshot. I found it (page 233 in the assembly manual), and took the part from the extuder (disassembled). The screws were not fixed, so the overall construction was a bit loose.

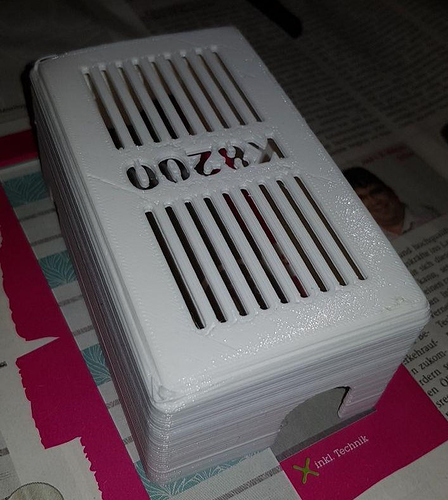

I am afraid I didn’t grind them properly. Most probably it was not enough. The picture now:

Video:

On my way in disassembling and reassembling I remember another thing that I found something unusual. The bolt that was fixing the cog on the motor was rather loose. It was so loose, it was slipping on the motor (I guess!). I drilled another hole into it (3.5mm), this time, it fixed nicely.

The set screw on the motor was one of the first things Dr Vegetable and I asked about.

More then likely this was the problem.

Hi @wrong_way,

Thanks for the reply. Sorry I ignored your questions. Technical language sometimes makes it harder to understand, and once other things are easier to understand, one opts for things that have higher availability (in term of understanding and language). But again: my appologies: I still need to work on my attentiveness.

(done with the reassebly, reheating the extruder)

Cheers,

Arturas

I think that should conclude this problem. The extruder is rotating and the PLA is flowing.

I am uploading the video of the 1st few minutes of the print, maybe you can comment on that a bit. The link will be

https://www.youtube.com/watch?v=nhWEvSYpyPU

(it is still being uploaded).

I am afraid, I’ll start another topic on callibrating the print. Any suggestions on that?

Cheers and thanks for patience!

Arturas

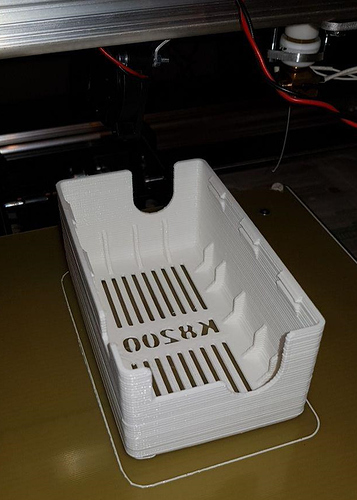

I’ve completed the 1st print. The results:

Overall looks good, doesn’t it? Two corners came off after 1mm or so, the borders are a bit unevent.

@Wrong_Way and @Dr_Vegetable thanks a lot for the support and help to adress the problems!

Comments?