[quote=“Meximelt”][quote=“ichbinsnur”]Have a look at my part here : thingiverse.com/thing:548827

It replaces the inner part of the stock k8200 extruder.

To mount the E3D V6/V5 (the 3mm direct, NOT the bowden version) or even other “groove mount” hotends simply slide it into

the slot at the bottom (right side in the picture) of the part and secure it in place with the cap.

The E3d V6 IMHO was the best upgrade i ever made.

It gives you way more precise extrusion, offers several different nozzle sizes,

and producs almost no blobbing and stringing if setup properly.

Also it has the ability to print higher temp materials, like nylon, as it is a full metal Hotend.

Just to clarify :

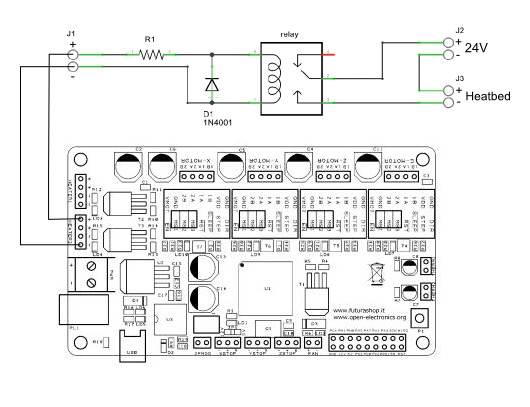

There is [color=#BF0000]NO[/color] option to run the [color=#BF0000]Controller[/color] of the K8200 on 24V.

But it prove a good idea to run the [color=#BF0000]heatbed[/color] from a [color=#BF0000]second 24V supply with a relay circuit or power expander[/color].

The heatbed then heats up way faster and can also reach 100°c easily, so you can print ABS reliable.

cheers,

Christian[/quote]

So now I’ve come full circle and can’t wait to try to print out your mount. I have spent enough time on this thing to rebuild in my sleep so I see the great idea you had combining the E3D mount with the ninjaflex extended guide up to the drive bolt.

There is definitely something addicitive to being able to print / tear down then use something you made yourself :-)[/quote]

Christian,

When extruding new E3D, large footprint thin parts, extruder starts to SLIP/lose prime, whatever.

I have retraction set to 0.5mm in simplify3d and was working,

but do you personally use any retraction with the E3D v6?

Or am I missing something else important?

I read somewhere re: jams that sometimes the bearing is pushing Too Hard on the filament prior to the hot end.

I make 7 half turns usually to load my spring.

Would appreciate knowing your experience on this! Thanks again for the board/schematic layout. I have all parts in hand now and will be at 24V on the bed soon hopefully!

See some pic related to my aborted print & extruder snapshots here: (Yes, there was not a big green blob on the nozzle while printing  https://www.dropbox.com/sh/4bk7243a2xc0jpz/AAB7IEEKzrbeETOaMlq8h0i0a?dl=0

https://www.dropbox.com/sh/4bk7243a2xc0jpz/AAB7IEEKzrbeETOaMlq8h0i0a?dl=0