So I have a Vertex Delta printer given to me by a friend who isn’t very good with such tech and doesn’t speak or read english very well. I am supposed to get this thing working and show her how to do things she needs to print. It was assembled by her and on her first try the nozzle supposedly hit the bed so hard it made a hole. I was told that she contacted Velleman and they have exchanged the build plate and some part that was causing the problem with calibration.

Then the printer was laying idle for a year and how I have it.

I already have an Anet A6 printer and have some knowledge on how to do stuff on this one, but different construction of Delta throws me off a bit.

I use Cura 4.0.0 for slicing. Sleds are fine, piezo hit detection works right and printer with about 8-10 iterations levels the bed.

My first problem was lacking material near one of the sleds. I have leveled the printer with bubble-level laid on printing table in 3 different directions (corresponding to 3 legs). Now the whole printer is leveled and problem still presists.

Here you can see how thin the skirt is. It’s already better that it was previously.

I’m not sure whether the problem lays in leveling the bed or not extruding filament properly.

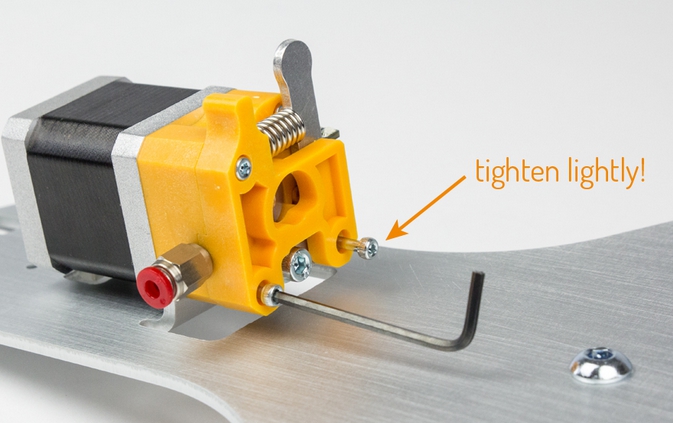

Another problem is the motor at the top pushing filament into the tube connected with the nozzle. At times it makes knocking noise and seems to be pulling PLA backwards. Today this was happening more often and the printer stopped detecting PLA midprint starting the filament exchange sequence and then having hard time extruding filament through the nozzle - no matter how many times I told the printer to extrude a bit more, it didn’t show up in the nozzle.

Third problem also occured today, but I had a glimpse of it previously. I wanted to see how the printer sees the axles X, Y and Z. When I turned the knob slightly the nozzle smashed into the bed, but not too hard and created this and another view of hole.

Today when the printer paused for filement exchange and didn’t want to extrude properly I autohomed it and restarted the print from point 0. I figured that since I didn’t restart the power it would remember the settings and would be okay without calibration. Boy, I was wrong. It smashed so hard it made a hole in BuildTak shown here and here.

When I turned off the printer and started next one with calibration everything was okay. The glass seems to be undamaged but hole in BuildTak warps the print bases and will probably need an exchange.

Also, is there anything I can do to stop the step enging belts from falling? Two days ago when trying out a print one of them fell off and whole printhead smashed into the print. One of the reasons could have been the fact that the belt was a bit loose. I stretched it harder and checked the others, but I’m afraid they will again fall off.