Hi All,

Things missing and not good working:

1 No hardware bed leveling. Print head dives into bed!

2 No tensioners for the toothed belts. Printer eruptions and shift.

3 No adjustable extruder, pressure on filament much too high for, for example, PET

4 Oil on the rods and balls gives dirty arms or clothes.

5 No heated bed. Problems with bonding.

Solutions:

1 Remove the 6 screws under the bed in the edge. Then place 3 springs at X, Y and Z (around the bulges) put 3 screws back. You can now fine-tune the bed. Idea by Willem de Zeeuw.

2 There are a few models of tensioners on Thingiverse.

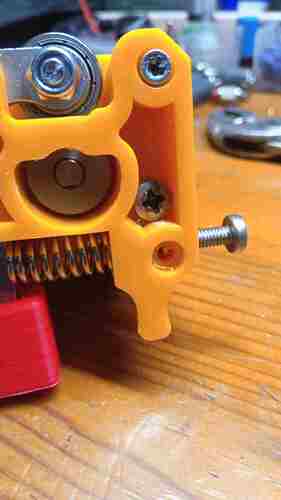

3 I took the extruder apart and changed the following. Removed the screw at the bottom right and shortened it so that it secures the lower part. To reattach the upper part, an M4 screw is placed in the recessed part. Then (work exactly) a 3.2 hole drilled in the heart where the spring is located, make sure you stay in the upper part, this works just fine! Then with a 10 mm drill (if the parts are firmly together) the hole of the spring deepened to the transverse hole of the removed screw.Then tapped M4 and screwed in a m4 screw, on the side of the spring a lock nut m4, but do not turn it through!!!. Now you can increase and decrease the spring pressure. In the case of soft filament, the pressure at rest is now just right.

4 Various metal and plastic slide bearings can be found on Thingiverse with special prints to make them fit on the K8800. The link is my version that I’ve been using for a while

I made them from PLA and have dry grease on the rods and balls. So that’s 2 in 1 !!!

5 The heated bed I got from 123d and also the temperature unit.

For the12v power supply, I use an old PC power supply.

If you want direct info you can mail me at t.emmelot at upcmail.nl

If you need housing for the temp board, you can find it here:

Kind regards,

Tom