Two days printer owner and very disappointed…

I bought the Vertex Delta two days ago.

The assembly was easy, even if the manual really could be improved!

Due to the large pictures the overview suffers. Better would be small pictures

because the pictures enlarged by clicking anyway.

Where is a detailed description of ALL menu items?

Where are the German translations of the documents beside assembly?

The assembly was done with great care and took about 4 hours for me.

Everything was done exactly according to instructions. Mechanically everything seems to be ok.

The next day first-time setup took place.

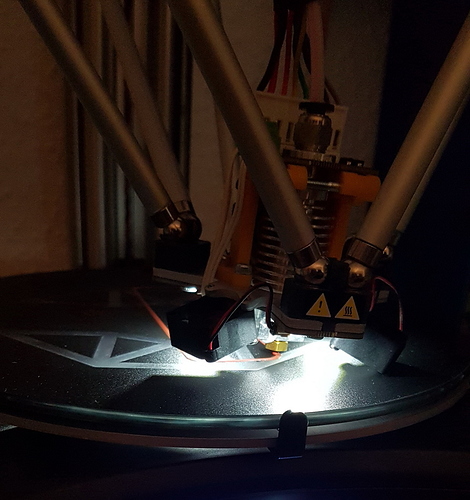

The printer performed an automatic calibration as described. The calibration sensitivity was checked before and is very high.

Nevertheless, during the first automatic calibration, the print head always hit the print bed with a distinct audible click. What I thought it would be correct - at this time – now I know better.

The calibration was completed with "successful"

I followed the instructions and tried to execute "CALIBRATE X, Y, Z, CENTER". Nothing happened. Then I stored settings as described and tried again. The result remained the same.

Then I’ve selected “Auto Home”, “Calibrate Hight” and “Auto Calibration” multiple times.

The printhead always stayed directly under the light barriers (without the "safe distance") and only performed the "light barrier test". In "Auto Home" and "Calibrate Hight" always once each and in "Auto Calibration" always three times. Multiple power-cycles had no effect.

So I selected "Restore Failsafe", which seemed to me the most useful in this situation.

After that, I chose "Auto Calibration".

The print head drove at full speed straight down into the print bed!

Only "Power off" stopped the steppers!

Power on again and I chose "initialize EEPROM".

Again I did "Auto Calibration". Now the print head does not hit the print bed so hard anymore

during calibration. Printer seemed to be OK then.

Then the first print test:

Data on SD card, loaded in the printer, printing started with calibrating the print head,

I think, because saw that I forgot to load the PLA down to the print head, I wanted to stop the printing at this point. So I selected “Cancel printing”

The print head moved sideways and then again crashed into the print bed!

Again the steppers could only be stopped with "Power off"!

Mature firmware ???

Power on, "Auto Home", "Auto Calibration" -> OK

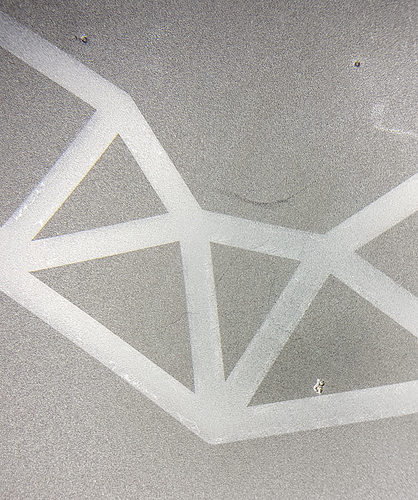

Next print attempt -> object gets loose from the print bed.

Canceling via the menu this time works without "head crash"

Third print attempt -> object gets loose from the print bed again.

Canceling via the menu this time also works without "head crash"

Are 10 meters filament for first testing really too expensive to include?

Better leave the tools away!

Filament used (because I could not get other in short time)

Renkforce PLA 1.75mm Red 485c, Printing Temperature: 190 - 220 ° C

Used temperature: 200 ° C.

This should work, or?

What else can I do so that the workpieces stick to the bed better?

And how to print plastics other than PLA without a heated print bed?

Conclusion after two days K8800: Two quirks in the print bed and no successful print.