Hi!

I recently got my 2 thermocouple-k amplifier adapters delivered. (Analog K-Type Thermocouple Amplifier - AD8495 Breakout) LINK

I wat touse them on the heatbed for more precise temp readings, and especially on the hotend, for getting higher temp range and mor precision.

The amplifier boards put out a voltage ov 1.0V per 100°C so i can easily go up to 400°C range for printing higher temp materials like nylon.

Also i will get mor precise temp readings as the thermocouple will be far more accurate than the usual thermistors, especially above 250°C.

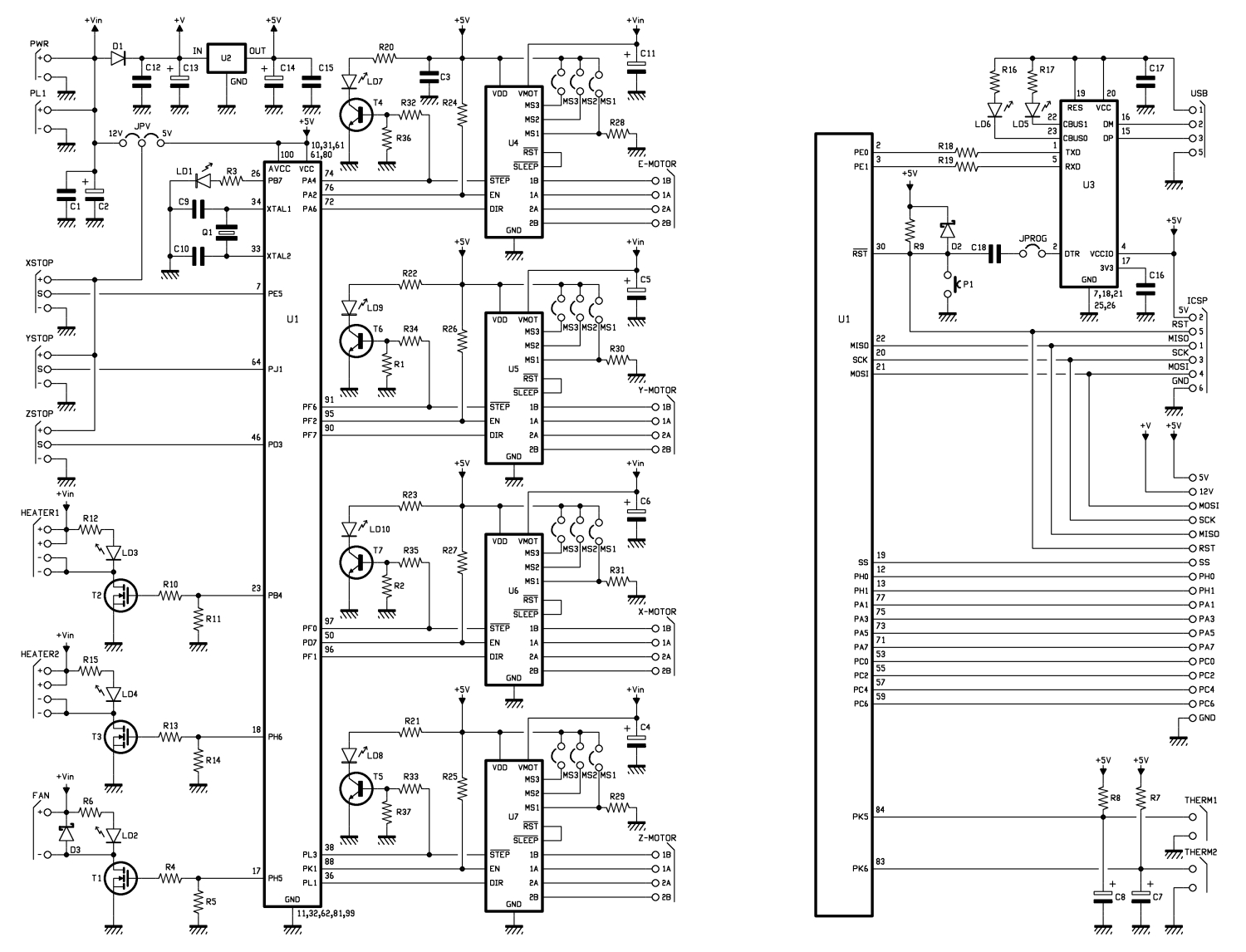

What i know by now, is that i have to connect the amplifier outputs to some ADC on the main controller.

There are 2 Options for doing that.

-

is desoldering the resistor/capacitor couple from the pcb and connect the output directly to the chip input.

(not my favourite cause i want to change as little as possible on the board) -

is soldering the output line to one of the 2 leftover but unwired ADC ports on the chip.

(i think i will try that first, cause today my hot-air soldering station arrived)

What i don’t completely understand is, how the thermistor tables in marlin are built. (what does the oversample value mean exactly)

Can someone point me out with that?

If someone can help me with reassigning the pins in marlin, so the firmware can use the leftover ADC ports for temp sensing

that would also be great.

Anyway, i will try to figure that out by myself too, but any hint is appreciated.