Hi RudydG,

I know such values depend not only on the hotend, but also on the extruder and other parts, but could you post your retract settings (length and speed) for comparison?

Cheers,

kuraasu

Hi RudydG,

I know such values depend not only on the hotend, but also on the extruder and other parts, but could you post your retract settings (length and speed) for comparison?

Cheers,

kuraasu

[quote=“kuraasu”]Hi RudydG,

I know such values depend not only on the hotend, but also on the extruder and other parts, but could you post your retract settings (length and speed) for comparison?

Cheers,

kuraasu[/quote]

I have 100mm speed and 3mm retraction.

But, don’t forget, my buldog XL extruder has a 5:1 ratio, all metal contruction.

Hi RudydG,

[quote=“RudydG”]I have 100mm speed and 3mm retraction.

But, don’t forget, my buldog XL extruder has a 5:1 ratio, all metal contruction.[/quote]

that’s not so far away from the original values, but the hobbed bolt could be an issue. Maybe I’ll get some test prints done next week. In any case, thanks for the info!

Cheers,

kuraasu

hi,

did anyone manage to solve the weak coherence between the layers? Since I switched e3d v6 I have the problem with weak walls and thin structures. It is easy to peal off the layer by hand. I have a 0.5 nozzle and I am printing with PLA.

cheers,

koke

I had same problem. Increasing extrusion width solved this.

PID autotuning did the the trick (not true, see my next comment)

The temperature control was not tuned for the new hotend plus thermistor. That was causing regular temperature flactuations during printing which was affecting the print quality.

I got PID values by running the autotuning commands and updated the firmware config.

Temperature is now stable and the weak cohesion problem is gone.

hi,

returned from holidays and working again with my printer I realize that the problem has not been solved.

The layers are not sticking well onto each other an the objects are feeble.

I tried increasing the default extrusion width and the infill but it didn’t solve it.

I also tried increasing the temperature but with no results.

I originally ordered the v5 but they mistakenly send me the v6. I wonder if they also made a mistake in the nozzle diameter and sent me a smaller diameter nozzle than the one I ordered. Is there a way to verify the diameter of the nozzle?

Any suggestions are appreciated.

koke

The V6 are dot-coded on the nozzle. 3 dots on nozzle = 0.4mm

0 = 0.25mm

1 = 0.3

2 = 0.35

3 = 0.4

4 = 0.6

5 = 0.8

Then you are one of the lucky who have got an e3d that actually works.

How can you have 0 ooze?? My e3d (which i have huge problems with) ooze like a dog with a cold.

No matter what filament type i feed it with. Nylon is worst.

thanks AndersE,

it’s a 0.4 mm nozzle. That is what I had in my slic3r settings.

I still have the problem with layers not bonding.

I will create a new subject about this with pictures of my problem. It could be that it’s not related to the e3d hotend.

Hello. I need some information. I have read this trend but i need a summery. What Change do i need to do to use the E3D-v6 hotend? Do i need to supply more power for the hotend and the two fans? How do i do that? Do i need to do anything ells except printer the holder for the E3D-v6? Im new at 3d printer so i need all the help i can get. The hotend on my k8200 doft work that well so need to buy a new hotend.

Hi xatazch

You can use the same heater cartridge with the E3D hotend as used on the original hotend. (That is, if your original heater is not glued)

So the only things you need to do are:

No big deal. No changes needed in the firmware.

Depending on the nozzle diameter you might need to change the settings in your slicer (I’m using a 0.4mm nozzle).

I find the E3D hotend much better than the original hotend:

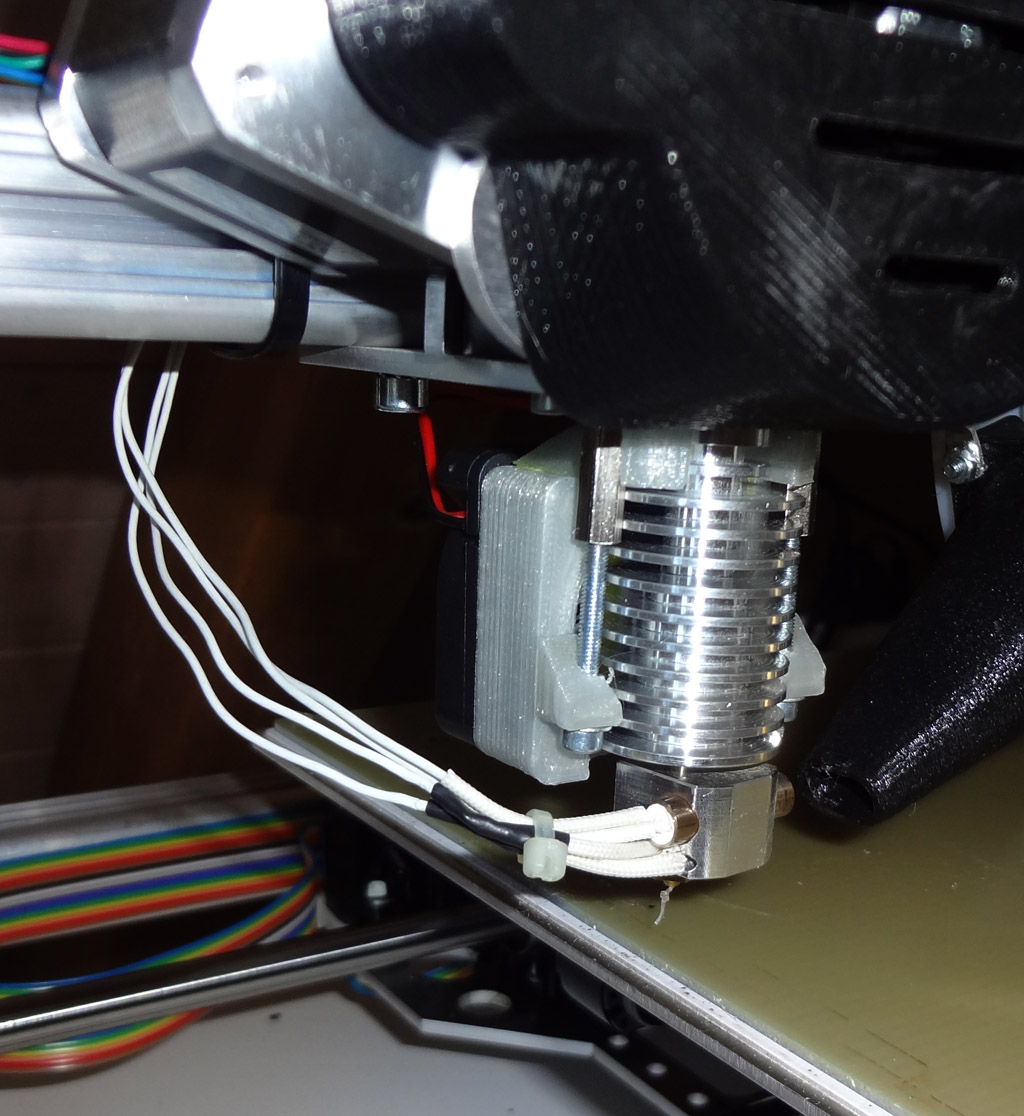

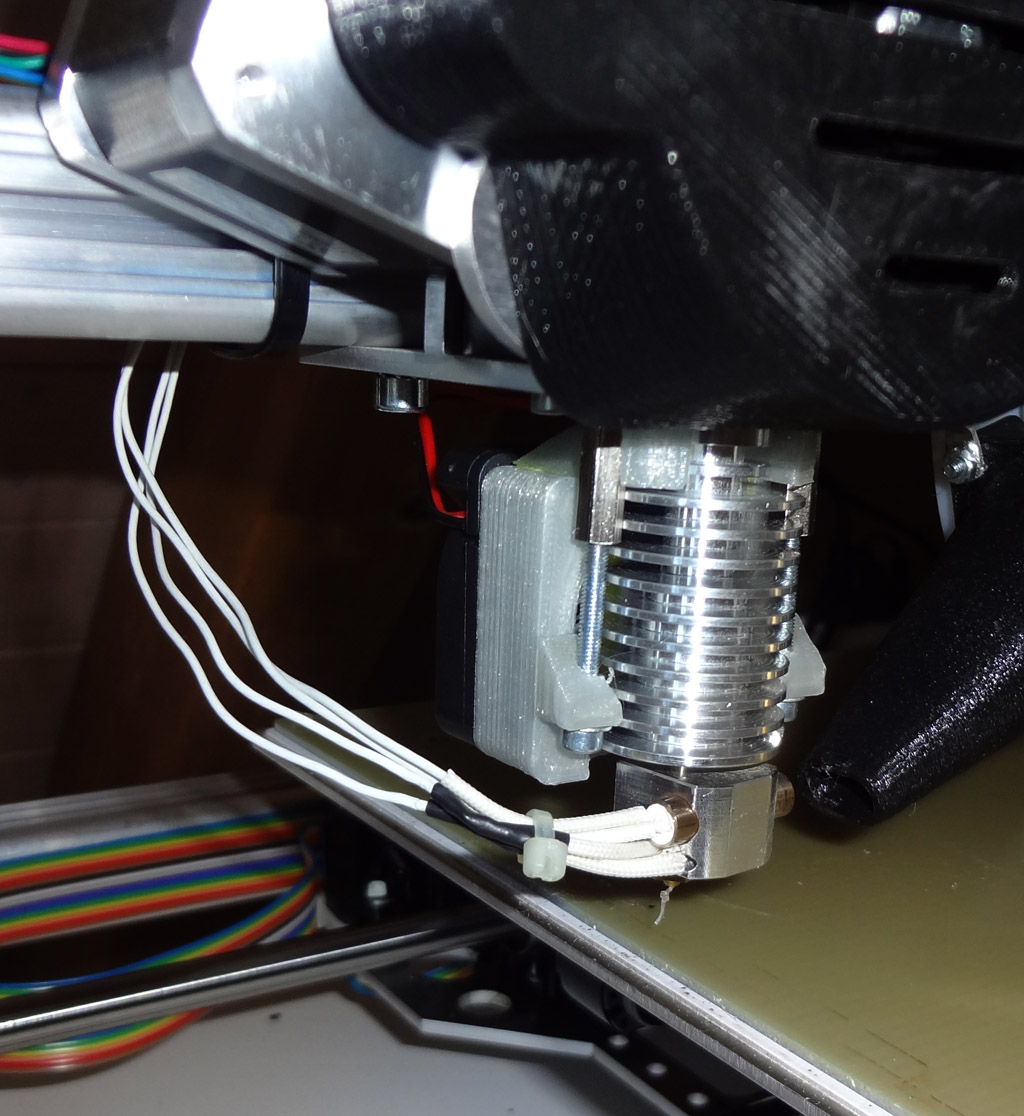

And this is what it looks like:

FYI: this is an older version of the E3D hotend, not the version 6.

Regards

[quote=“Deskstar”]Hi xatazch

You can use the same heater cartridge with the E3D hotend as used on the original hotend. (That is, if your original heater is not glued)

So the only things you need to do are:

No big deal. No changes needed in the firmware.

Depending on the nozzle diameter you might need to change the settings in your slicer (I’m using a 0.4mm nozzle).

I find the E3D hotend much better than the original hotend:

And this is what it looks like:

FYI: this is an older version of the E3D hotend, not the version 6.

Regards[/quote]

Thx for the reply. My hotend is on its Way to me now. :). So i can use the same powersupply? Dont the E3D (fan and heater) need more Power then the original k8200 powersupply has?

Yes, you can use the same power supply.

The only additional power is used by the fan (if you use the original heater), and that’s not much…

Regards

[quote=“Deskstar”]Yes, you can use the same power supply.

The only additional power is used by the fan (if you use the original heater), and that’s not much…

Regards[/quote]

Ok so you dont change the heater. But is the heater on the k8200 as good as the one on the E3D-v6?