The Cura engine on Repetier frequently inserts walls into holes of openings in the part. Most of those walls are a single layer thick, but I have seen up to three layers and that is messy to remove without damaging the part.

Can anyone help with this?

Could you include some screenshots of the design and of the slicer screen, showing these walls? Just for us to understand better?

Thanks.

Is the slicer saying anything about the drawing not being manifold?

I would be glad to but don’t know how to post the images. All I get is the link. Can you help?

No, the stl file is fine.

Do you have a link for the STL?

Seems you can drag a picture file into the editor frame. ![]()

Sorry that didn’t work.

You will need to browse for it.

Looks like I was progressing, but then I got the message that only 32 kBytes are permitted, obviously not enough for any picture. Do you have an email address I can send those to? If you want to keep your personal email private, here is my email address; please ping me: kmeyer5063@aol.com

Testing: pulling in a 340kb sample image…

Weird, seems to work from this end - even though it turns out as 228kb once uploaded… Anyway, no worries - I’ll email you my gmail.com address, you can send it there.

Hi Klaus,

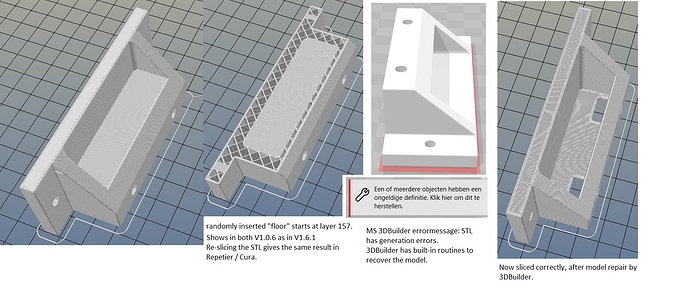

I received your files, thanks - I loaded the gcode file into Repetier / Cura & to my amazement I see that it actually does insert an extra wall in te object. Turns out, that the STL generation introduced an error, that ticks the slicer off to do these unexpected things. Hope I can fit the picture I put together into this message:

[Click image to enlarge]

As I found a while ago, when using Repetier / Cura, Microsoft’s 3DBuilder is your friend… The only thing you need to do, is load your STL & it will check for any errors while loading & will alert you, if it finds something. It can then auto-repair the model for you.

Edit: After placing the above, I had a look at the pulley model you sent. In my V1.0.6 and V1.6.1 versions of Repetier / Cura, I did get all 4 holes on the 1st layer - but the fact that you only got 2 is mostly due to the same issue as above - as 3DBuilder also indicates generation errors for the pulley’s STL file. So… I can’t reproduce the error, but I’m pretty sure it’s the same cause.

In case you don’t have 3DBuilder, I’ll send you the repaired STL files via email - but that should do the trick…

Edit 2: I see, Wrong_Way was expecting the same issue - the slicer normally isn’t that responsive on noticing these errors, 3DBuilder is quite a bit more sensitive to them. Tossing your STL’s into 3DBuilder, as part of a standard check, prior to printing, will help you prevent these errors. ![]()

Gentlemen, thanks for your wonderful work. This is good news for me since I was getting pretty frustrated by now. After having used the 8400 for over a year and learning how to design stuff for 3D printing, this seemed an odd thing to have to live with.

Thanks again

Klaus Meyer