Hi Folks,

seems I found a solution for my problem:

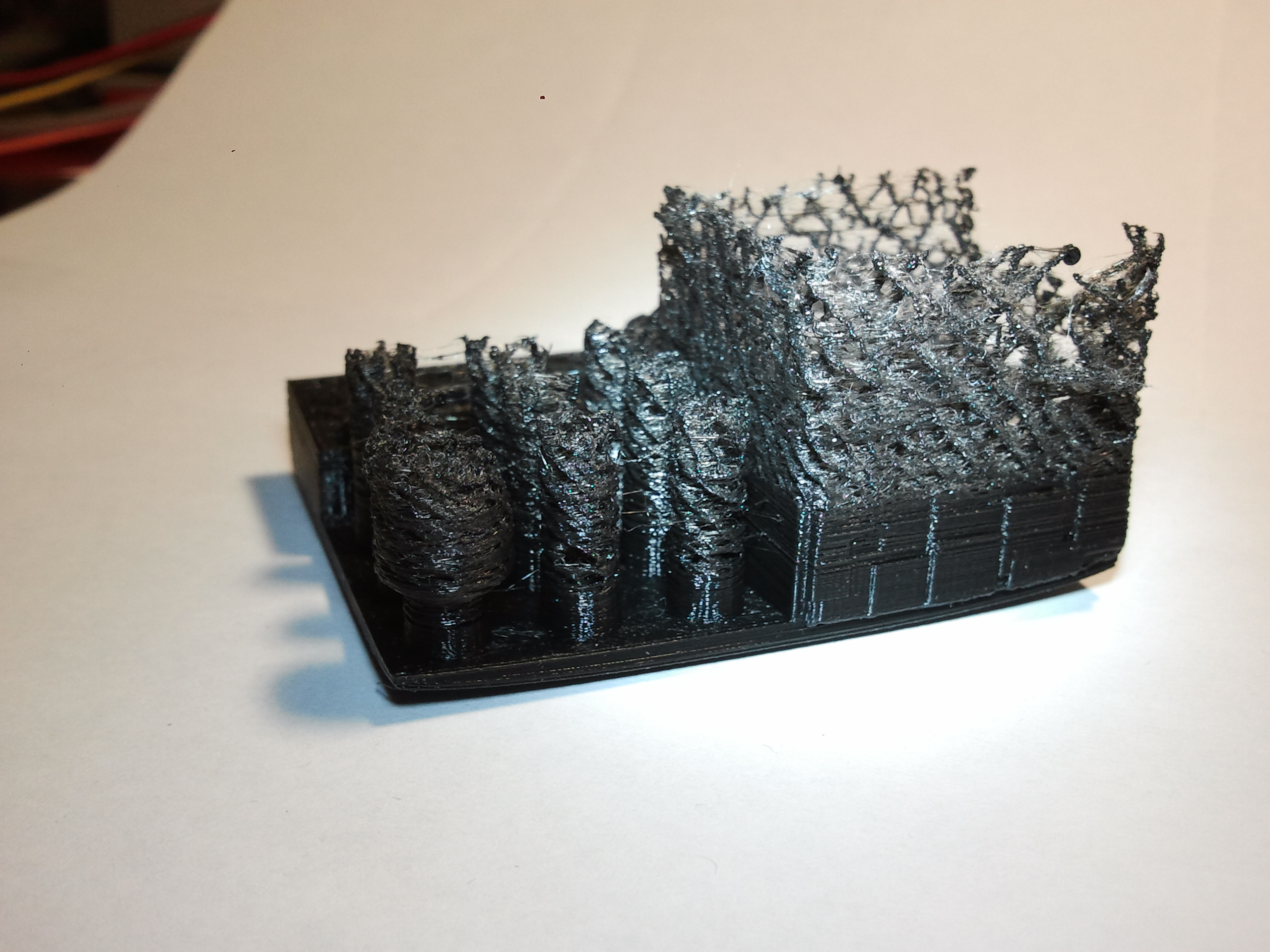

I am sure there was something inside the nozzles which was bigger than the 0.35 hole.

After completely decompose the hotend (that’s unlikely not an easy task…) I used

the ‘Burnout’ method. Yes sounds hard, but I think this was the only way which helped.

I took a blowtorch and heat it nozzle up until the contained filament gets fire (if you

want to do the same do it outside!). Than I cleaned the inner surface with a dental

brush (used to clean braces).

Now I got prints which are pretty perfect!

My conclusion:

- Do not wait too long with a semi clogged nozzle. If it happens again and again

do clean the nozzle in a right way! - Next project: Build a foam holder to clean the filament in front of the extruder.

But nevertheless my black PLA material tends to a semi clogged nozzle.

So I do not use this material (vendor) anymore. It’s better to buy quality!

Many thanks to all of you for your tips and tricks!

It’s totally correct to consider everything what was said here.