[quote=“JustMart”]Hello again,

First of all i have 2 old computer power supply’s, would any of them do?

- http://i61.tinypic.com/29f8aax.jpg

-

http://i57.tinypic.com/2cz2ddk.jpg

[/quote]

I think both supplies will be too weak to power the heatbed properly.

Have a look at these :

reichelt.de/MW-GS120A24/3/in … anwell+24v

reichelt.de/index.html?&ACTION=446&LA=446

I use the first one by now, but i’m currently upgrading to the second, for a different headbed PCB with more power.

For the MOSFET:

P Channel

To turn a P channel MOSFET on, you apply a negative voltage to the gate. This voltage is negative relative to ground. In a circuit, you connect the P channel MOSFET’s source terminal to a positive voltage supply and the drain to a resistor connected to ground; the resistor limits the current flowing through the transistor. The circuit diagram symbol for a P channel MOSFET has an arrow pointing away from the gate.

N Channel

An N channel MOSFET turns on when you apply a positive voltage at its gate terminal. The voltage is greater than the positive voltage supply at the drain terminal. A resistor between the positive supply and the drain limits current; for an N channel MOSFET, the source terminal connects to ground. The circuit symbol for an N channel MOSFET has an arrow pointing toward the device’s gate.

So you would need an Logic-Level (5v signal) compatible N-Channel MOSFET

Also make sure the chosen type has an extremely low “on resistance” (RDSon) of 0.005 Ohms or less, to prevent heating it up too much.

For example : reichelt.de/index.html?&ACTION=446&LA=446

The on board MOSFET can’t take the current needed for the heated bed so you need to insert a dedicated circuit that can.

Two options :

-

Buy a ready made one :&

-

Build one yourself :

Connectors and wires

one 2 pins : [reichelt.de/PSK-254-2W/3/ind ... SEARCH=psk](http://www.reichelt.de/PSK-254-2W/3/index.html?&ACTION=3&LA=446&ARTICLE=14857&artnr=PSK+254%2F2W&SEARCH=psk)

and one 4 pins : [reichelt.de/PSK-254-4W/3/ind ... SEARCH=psk](http://www.reichelt.de/PSK-254-4W/3/index.html?&ACTION=3&LA=446&ARTICLE=694&artnr=PSK+254%2F4W&SEARCH=psk)

Molex connector to plug on the controller board.

[img]http://cdn-reichelt.de/resize_70x70/web/artikel_ws/C151/PS25WEIS.jpg[/img]

DON'T FORGET TO ORDER THE CONTACTS! : [reichelt.de/PSK-KONTAKTE/3/i ... SEARCH=psk](http://www.reichelt.de/PSK-KONTAKTE/3/index.html?&ACTION=3&LA=446&ARTICLE=14861&artnr=PSK-KONTAKTE&SEARCH=psk)

[img]http://cdn-reichelt.de/resize_70x70/web/artikel_ws/C151/PSKKONT.jpg[/img]

2 x 0.5 or 0.75 mm (speaker cable or 2 pole mains wire for instance) wires for the heated bed. Smaller wires for the +15/24V and the thermistor.

Soldering iron and solder

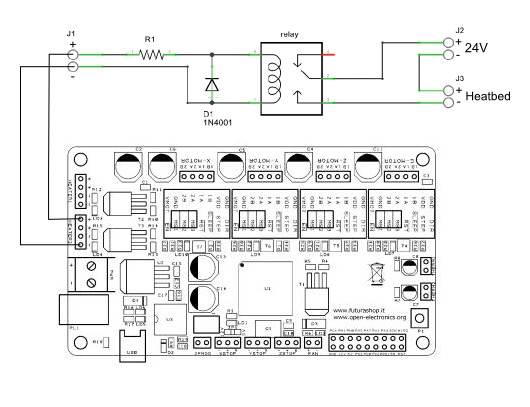

Below you can find the schematics and implementation to build a power expander yourself :

Components list :

1x IRLU8743PbF MosFet

1x SFH610A-1 Optocoupler (to isolate the microcontroller from the power circuit)

1x 1N4148 Diode

1x 1.2K Resistor

1x 2.2K Resistor

1x 2.7K Resistor

2x 2-pole Terminal block

1x 4-pole Terminal block

1x Strip Grid PCB

Here is a link to the WIKI article :

The article is for the k8400 (vertex) but it’s basically the same for the K8200

k8xxx-3dprinters.crimed.be/w … ted_bed/de

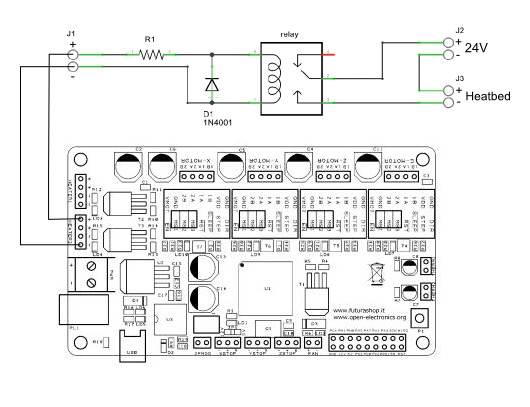

And here is the relay solution :

The diode (D1) protetcts the Mosfet on the Controller board from voltage spikes generated by the relay coil.

The resistor (R1) limits the current that flows to the relay coil, to prevent damage.

You need to calculate the needed value based on the rated current of your relay coil and the 15V output of the Heatbed output.

For example if your relay coil draws 30mA : R=U/I 15V/0.03A=500Ohm

Make sure The relay can take the current drawn by the Heatbed. (about 4.5A at 24V for the stock k8200 Heatbed)

cheers,

Christian