Issues with crashing of the printer head. I calibrate the height, I auto calibrate and store the settings. When I start to print the head crashes very often in the left corner. The piezo sensors seem to work, increased sensitivity to max but do not solve the issue. My printer bed is already completely ruined from several crashed. Excess of bed pad has already been removed to avoid any friction. Think the sensors are still the issue…. Please advise to solve. https://youtu.be/QAgHOrlDkW0

@Mathieu ,

This seem a calibration problem.

Can you check whether the print bed (glass) is clamped between the 3 gray studs?

The glass must lie on piezos, and where you can still move the glass (front to back and sideways).

If not, file all 3 gray studs with a flat file, until there is enough play.

“If the bed is clamped between the studs, there is no correct sensing anymore between the 3 individually piezo sensors on each corner. And so the calibration can never succeed, even though the printer says calibration okay.”

After that, set the sensitivity potentiometer back to " middle " position.

Reset the printer: Settings => Restore Failsave => initialize EEPROM => store settings.

Then calibrate again in follow order:

- Auto Home

- Calibrate Height

- Auto Calibration

- Store settings.

This is the way to check the piezo sensors individually:

Test the piezo sensors separately. Remove the print bed (glass) from the sensors. Set the trim

potentiometer “sensitivity setting piezo” to the middle position. Then tap the black pad of the piezo

sensors with two fingers, once gently and a second time a little harder. Make sure the red LED lights

up every time. Do this for each piezo. If the LED does not light up or is irregular to the other piezo

sensors, there is something wrong with the piezo sensor(s). If so, it needs to be replaced (or several).

Hope this will help to solve the problem

Met vriendelijke groeten,

Technical Service

Thx, this indeed is the trick. I filed the three extended studs a little and now seems to work fine. The reset of the eeprom aslo helped.

Next problem….

Printer starts to deviate after a few layers. Made two video. I deleted again the eeprom memory and performed everything time the height and auto calibration and stored the setting. After a few layers the printer start to deviate from original coordinates…

Thx for helping

Dear @Mathieu ,

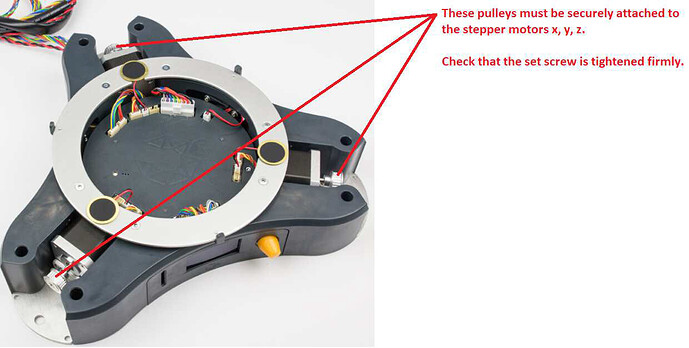

Check that all pulleys on the stepper motors (X, Y, Z) are firmly tight. Normally it should be screwed on

tightly from the factory (the adjusting nut). Sometimes it happened that these were loose. Page 20:

§Motor sub assembly: “K8800-BASE-ASSEMBLY INSTRUCTIONS.pdf”.

It is best to check this by placing a flat screwdriver between the pulley and stepper motor. Then try if

the pulley can move with a screwdriver, you can use some force for control. This must not move!

If so, fix the pulley through the adjusting screw.

If these pulleys are loose, the print head changes position (line) during: Homing, calibration, printing

=> Result: wrong calibration, rods and or print head loosen, printhead presses too hard against bed,

rotation of the bed during printing, layer shifting, etc.

Best Regards,

Velleman Technical Service

Thx. One polies from the motor indeed was loose….

Having too many other electronic devices connected to your printer might cause your printer to lose power and turn off. Make sure the USB cable runs directly from the computer to the printer. note: Try a different USB cable if one is available.