Hi, I am extremely new tro 3D printing to begin.

I would consider myself capable of learning the fine art of hobby 3d printing, as I have built and managed

to produce a few failed prints from my k8200.

The build was great, and I am super proud that I managed to assemble and wire the printer correctly first time.

I just have some issues while printing.

-

The orinter is very temperamental with it’s connection. When connected to Repetier it sometimes responds to commands using the manual controls, and it sometimes doesn’t. I find myself having to re connect, or push the little clicky butrton on top of the circuit board (i assume this clears the commands, or like a reset or something)

-

I have had some issues with the ABS coming through the extruder, and have been giving it a helping hand at the beginning of prints, then it seems to flow ok. However, the 4 test prints I have done, the prinmter disconnects itself from my PC halfway through prints.

It just aborts the connection, and a com port error appears.

These are my two main issues, along with a few motor issues which I think I can rectify.

If there is anyone that can give me some advice on connections, firmware issues maybe, I would be most appreciative.

I am using Windows 7 64bit and Repetier host V0.95F

Many thanks

Matt

Hi welcome to the Velleman forum.

Are you using the USB cable that came with the printer?

Have you tried it on a different computer?

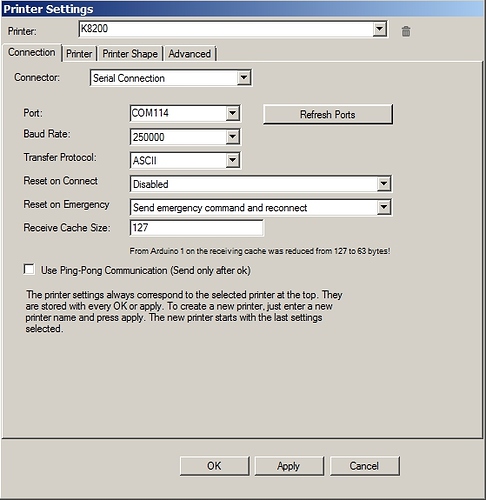

Do the printer settings match the ones below with the exception of the com port

.

Since you are just starting you should use PLA until you get the hang of using it.

PLA is a lot more friendly and forgiving then ABS Print temp for PLA is around 190c ABS 220c.

If you set the stepper drivers to 0.425 you should bump them up to 0.5 do not go over 0.6

1 Like

Hi Wrong_Way

Thanks for your reply.

In true noob fashion, I did not even think to try the most obvious fix’s first ie. cable, computer etc.

I am not using the cable that came with the printes as it is about 30cm long! I need at least a metre.

My printer settings were almost as yours, with the exception of Transfer protocol and reset on connect. I have rectified.

And This is the first computer I have tested the printer on, and have no way of trying another computer.

Also, I only have ABS spool at my disposal, so I will order some PLA and try with that first.

Could I ask for some advice on the extruder - hot end - nozzle?

First question, does it matter the diameter of the material going into the extruder, if the nozzle is 0.5?

Is there a specific diameter material that works with specific nozzles etc?

And lastly, I very much appreciate any help you can, and have already given me, thank you.

Matt

Your cable might be to long.

Try the one that came with the machine.

Reset on connect will cause a problem if it is not set to disabled.

The plastic for the stock K8200 has to be 3mm.

After you have used that machine for awhile and you want to control it from across the room you may want to look at using a Raspberry Pi and Octoprint.

https://octoprint.org/

Also never start a print and leave the house.

2 Likes

Some sound advice there!

I will try and move my pc tower closer to use the stock cable.

And I iwill make sure to get some 3mm PLA to play with.

The prints have been getting better and better, but now I have an issue with the print shifting across about 5 mm in the middle of the process…

Did you readjust the stepper drivers to 0.5 volts?

1 Like

Also check the pulleys on the motors.

Make sure they are tight.

Don’t strip them.

1 Like