Hi everyone,

K8800 is my first delta, although not my first 3D printer (about 6th in total, including SLA, and various cartesian FDM printers - just so happens i never trusted or liked deltas).

Assembly went quickly and easily (about an hour), first prints were nice for a 0-configuration, ready-to-assemble kit, but then i started noticing issues…

First and foremost, parallelism, or lack thereof. My test cubes, and various prototype prints end up with sides that are not straight, but curved. Not all of them, just one, and it’s consistently the same one. Any clues on what to look for?

All three belts are tensioned just enough (slight twang, but not overly tight), everything’s lubed and oiled up, there is no binding in any of the arms, and all carriages move freely.

Second, i had one of the belts always slip near the bottom of the range, until i pulled it out, bent it the other way a bit, and put it back. Now it’s fine (so far). Whoever thought of using idlers that are unsupported on either side must’ve never printed for longer than the demo keychain. That’s a serious design flaw, just like the bed that’s not fixed, but can be nocked around by the nozzle.

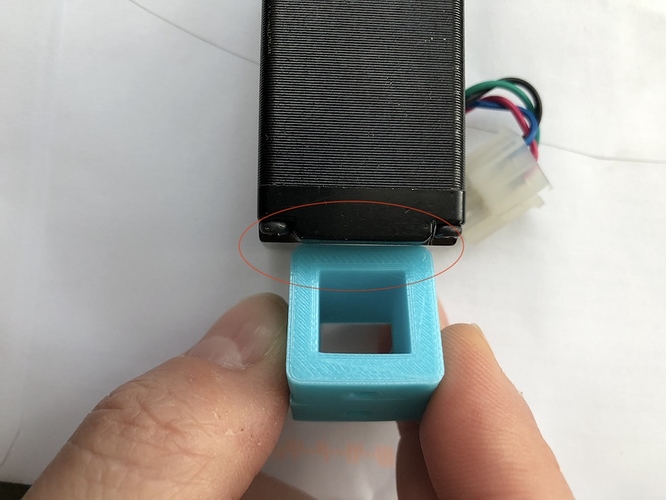

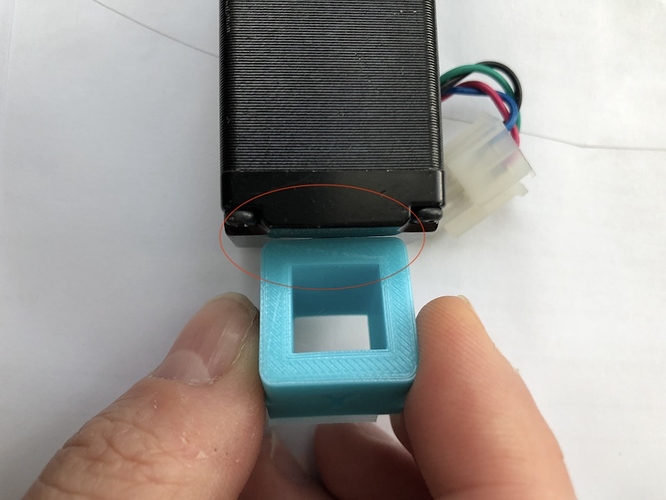

I’ve noticed someone posted a fix in the shape of a clip - has anyone tried simply adding a small washer and then a large washer to the front and back of the bearing stack? (Small to stay in contact with the stator of the bearing, then a big one to prevent the belt from sliding off - the issue with this design is the belt would rub against it, instead of it rotating freely with the washer.)

And finally, third thing - i occasionally get X-Y drifts - i can’t call them skips, because they happen over very gradually, over a multitude of layers. To me this smells awfully like the pulleys on the steppers are slipping. Before i start looking into that, does anyone have a different suggestion / debugging starting point?