I noticed that my printer isn’t printing perfectly straight. For example, if i’m printing a cube, one or more edges aren’t straight. The nozzle scrathes the surface on every layer while travelling. I tightened the belts and I lubricate the printer before every print. Does someone know how to fix this problem?

The rubbing on the print might be due to the z offset being too low, the printhead extrudes too much plastic for the nozzle height on the first layer and it gets pushed around the nozzle creating ridges that will interfere with the movement when printing the next layer. This usually sorts itself after about 3 layers. About the lines not being straight, can you estimate by how much? does the effect depends on the line of the line, is it perhaps plastic shrinking not evenly? There are many factors that might not necessarily be mechanical.

Can you post some pictures?

Sorry for the waiting! I had a really busy month. I’m still having the same problem, the printer scratches the surface realy hard when traveling. Even reducing the z-offset doesn’t help. If I don’t reduce the speed to 50%, the print will fail. When a print fails, the nozzle slams into the print and then the head detaches. I hope to fix this problem.

I can’t upload my picture’s cause they’re to big. On what site can I post them?

Try imgur. Or if you have a dropbox (or similar) account you can share from there.

https://imgur.com/NcYWQSk

Here’s a picture of when the head bumped into the print while traveling.

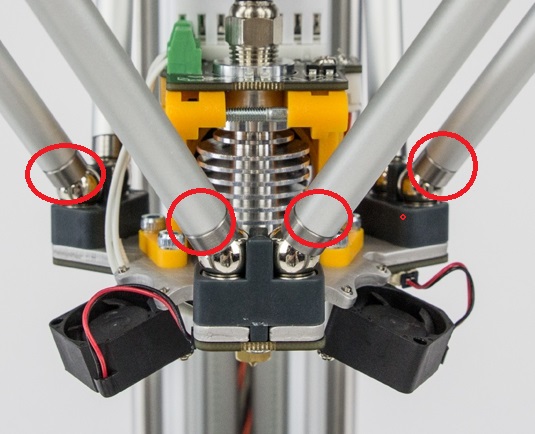

Just wondering if any of these are coming loose

Check the top as well

I checked all of them, but no one was lose.

It’s not exactly clear what do you mean by rubbing, in the picture there is a blob of filament on the top surface, is this due to the head rubbing so hard that that the effector detached and stopped in this spot or did you stop it there yourself?

Generally speaking any FFF printer rubs the surface quite often while travelling, you can sometimes even hear it quite loudly. This should however not cause any issues as the affector should be able to go where it is supposed to anyway.

Try these:

- Set Z-hop value to something like 0.5mm. This setting should be present in every slicer, it makes the nozzle move up with each retraction, travel to the new spot and then move down again. This hop will minimize rubbing on moves that use retraction (travels usually) but it might increase stringing.

- Use shims to better secure the glass bed. The bed on the Vertex Delta is constrained from moving laterally by three plastic hooks, it must however rest on the piezo sensors free to move up and down. What I’ve noticed is that the bed in some orientations can be quite loose between those hooks and when the head rubs on the print the friction moves the bed and the print a little which causes “not straight lines”. I tend to put plastic shims (about 0.2mm thick) right after bed levelling between the glass and the hooks in two out of three places which secures the bed laterally and that makes every print perfect.

Could you also tell us what slicer You are using? It might make troubleshooting easier.

While traveling over the print, it slammed a hole in the print. One or more couplers detached. This is what you can see on the picture. Direct after it detached, I powered off the printer. I’m using Cura as a slicer software with the presets for the vertex delta.

I will try to experiment with the different settings. I’ll let something know as soon as possible. Thanks a lot for helping me out!

Hmmm… In that case You can try to check wether all of the belts and pulleys are tight and the motors drive the axes properly. Do that by homing the machine and immediately after it stops try to move the effector by hand, it should feel stiff and the motors should hold back with reasonable force. You can also try to move individual axes up and down too. Keep in mind the motors only hold for some time before shutting off.

I homed the printer and did what you said. The motors feel indeed stiff and I can’t move the effectors easely. Could it be my oil that I’m using? I’m using oil with a teflon surface protector.

Honestly I think the oil does not impact the quality too much but the longevity. The axes are free enough to operate without any lubrication. Also I think the oil you’re using is fine, the bronze does not handle too many forces in a 3d printer appliction and anything that reduces friction makes it happy.

Does the problem happen everytime? Can you show us the lines that are not straight that you mentioned?

https://imgur.com/DK2aM9S

This is the underside of a print. You can see that the print isn’t straight at the end of the ruler. Am I to critical or is this not normal?

Hmmm, I don’t quite see what you mean by the end of the ruler, sorry. You can try to mark the image with troublesome areas. Maybe I’m distracted by how good that brim looks

You can try printing with skirt only if the print has a footprint big enough, buildtak handles it beautifully and You don’t need to clean anything up after printing.

what is the travel speed? May be it is too fast. The printer computes the stepper movements in 60 (stock firmware) segments per seconds. Faster moves will have more deviation from straight lines. You can also increase Z-hop and play with combing settings.