Hi All,

So what are your thoughts on the new E3D Titan Extruder?

http://e3d-online.com/Titan-Extruder

It looks pretty good, very easy to change extruders between 1.75mm and 3mm.

But how to mount it on my K8200?

Regards,

Neil.

Hi All,

So what are your thoughts on the new E3D Titan Extruder?

http://e3d-online.com/Titan-Extruder

It looks pretty good, very easy to change extruders between 1.75mm and 3mm.

But how to mount it on my K8200?

Regards,

Neil.

yes a very nice looking extruder and the price is not to bad if only we could fit this to our printer???

I have one, still trying to design a mount for it. Will share if I get something that works.

Hi all

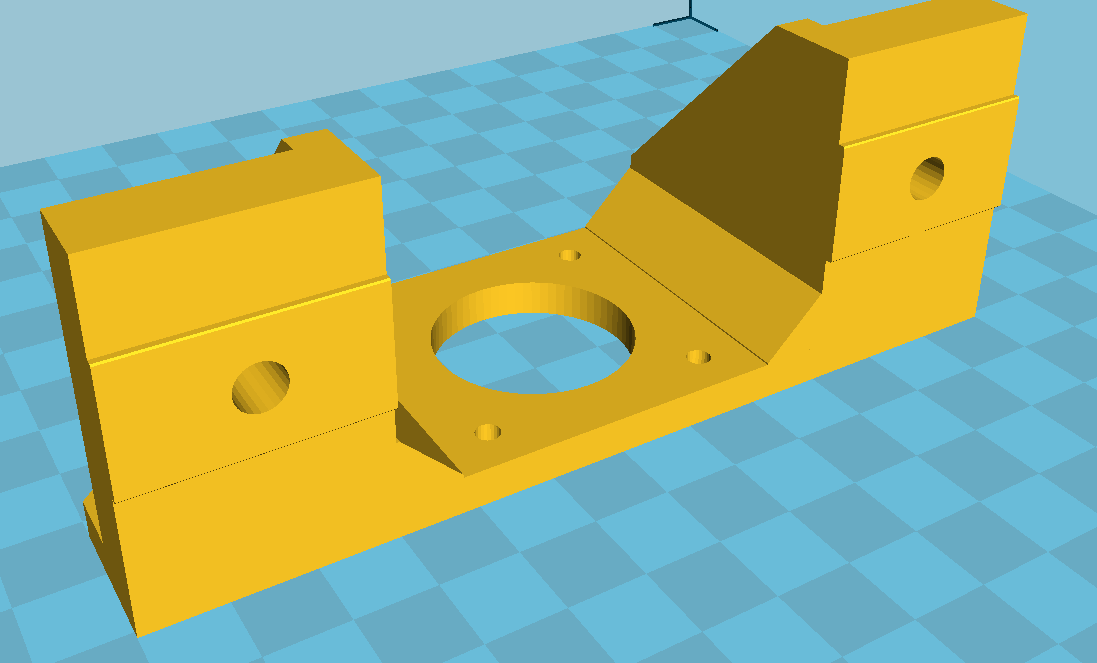

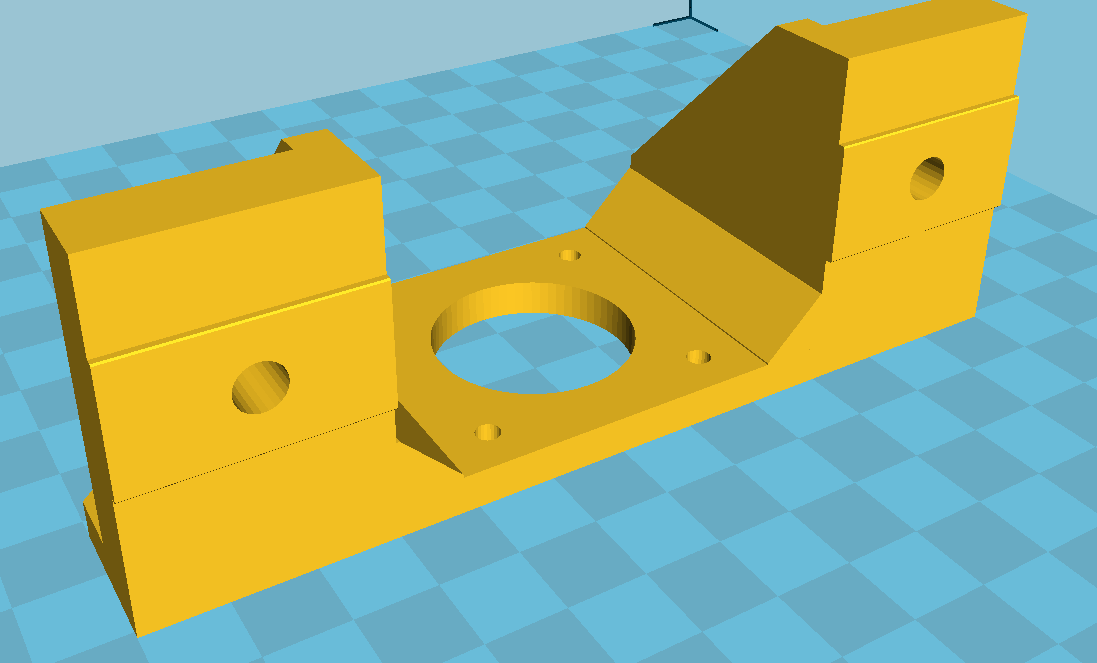

This is what I’ve designed for the E3D Titan extruder together with the E3D v6 hotend for mounting on the K8200 frame (quick and dirty, but very tough).

Underside of the nozzle is approx. 48mm below the underside of the Z frame, so Z axis end stop needs to be adjusted (but this also increases the max. Z axis travel).

Interesting. Can you post this on Thingiverse?

Thanks Arnold

[quote=“Deskstar”]Hi all

This is what I’ve designed for the E3D Titan extruder together with the E3D v6 hotend for mounting on the K8200 frame (quick and dirty, but very tough).

Underside of the nozzle is approx. 48mm below the underside of the Z frame, so Z axis end stop needs to be adjusted (but this also increases the max. Z axis travel).[/quote]

Hey deskstar!

How are your experiences with that extruder so far?

I want to change mine too evetually.

Hi @Deskstar,

I’m just placing my order for the Titan extruder.

Could you please share your design, ie Thingiverse or as a download here.

Thanks,

Neil.

Im curious as what to the advantage is? At least for the K8200, after upgrading the hobbed bolt, I dont have any real problems with the extruder. K8400, different story, I might be tempted to try a pair of those on that one.

Hi I have came up with a solution that requires no printing extra parts other than the stepper mount you can get with the titan extruder.

I used a spare backplate from that digital indicator you can see on one of the photographs. I drilled out larger holes added washers and added a foam vibration dampener behind the motor and the aluminium frame.

The 70mm m3 screws came from ebay.co.uk (ebay.co.uk/itm/261540874752? … :MEBIDX:IT)

This works very well, but the virtical z axis frame needs moving back a few cm to adjust for the 0.0 homing being outside the build plate. It also allows for me to slide the extruder along and use the digital indicator to level the print bed.

Hi @abrooksdavis,

Great idea. I also noticed your cooling fans. Where these fan ducts designed for this extruder mount?

Do you have these available for download?

Thanks,

Neil.

[quote=“NW27”]Hi @abrooksdavis,

Great idea. I also noticed your cooling fans. Where these fan ducts designed for this extruder mount?

Do you have these available for download?

Thanks,

Neil.[/quote]

Hi Neil. I created those mounts some time ago for the E3dv6 hotend. Untill im up and running i just cut the top end of the finned metal heatsink mounting part. Its not ideal but it will do the job untill I make a new one specifically for the Titan extruder

My designs are on thingiverse:

Once my printer is up and running (having a horrible time getting an E3D PT100 thermocouple upgrade kit to work) Ill be making a better mounting system for the fan ducts, probably with mounting sites built into the titan spacer thats needed. Just using the one that came with it at the moment

Not pretty, but this is the mount I’ve knocked up.

[quote=“washout”]Not pretty, but this is the mount I’ve knocked up.

http://www.thingiverse.com/thing:1556297[/quote]

Do you have a picture with this mounted on the printer? And will this extruder work with the standard stepper motor? I’m guessing it will need some reprogramming for extrusion lengths to be correct?

[quote=“kjriisne”][quote=“washout”]Not pretty, but this is the mount I’ve knocked up.

http://www.thingiverse.com/thing:1556297[/quote]

Do you have a picture with this mounted on the printer? And will this extruder work with the standard stepper motor? I’m guessing it will need some reprogramming for extrusion lengths to be correct?[/quote]

I don’t have any pics andvI’ve since updated to a chimera which I’m having to do as a Bowden setup at the moment so I can’t get any.

It did need me to move the upper frame, but the Z depth was similar to the stock extruder with an E3D V6. I’m using 420 steps per mm.