I’m here again. Maybe I have allot of stupid questions, but yeah, I’m 15 years old and this is my first printer, I’m proud I can print already.

I liked the build, I have the printer OK now, but I have a few things I don’t know or where I’m unsure of. I hope to get some good input, and maybe it can help other people tho?

I didn’t know, and actually still don’t know how thight I have to set the belts. I see people changing the belt tensioners, but also people that don’t do it. I’m not sure if I have to much or to less tension.

My printer itself makes allot of noise, when doing infills, the printer vibrates and makes a loud noise, like there is play on the rods and the bearings and it’s going to shake lose or something. This causes all other things to shake to, like the bed. I don’t know if that is bad or something?

After a week, I also heard a ticking noise from the fan, the big one on top of the printhead. Don’t know why, but it is irritating… all those sounds get me worried…

I printed the Z-axis stabelizer, because I could see the axis wasn’t turning straight, but now the printer makes more noise from the Z axis then it was doing before. How can this be? Also got the rod and motor shaft out of the coupler a bit more.

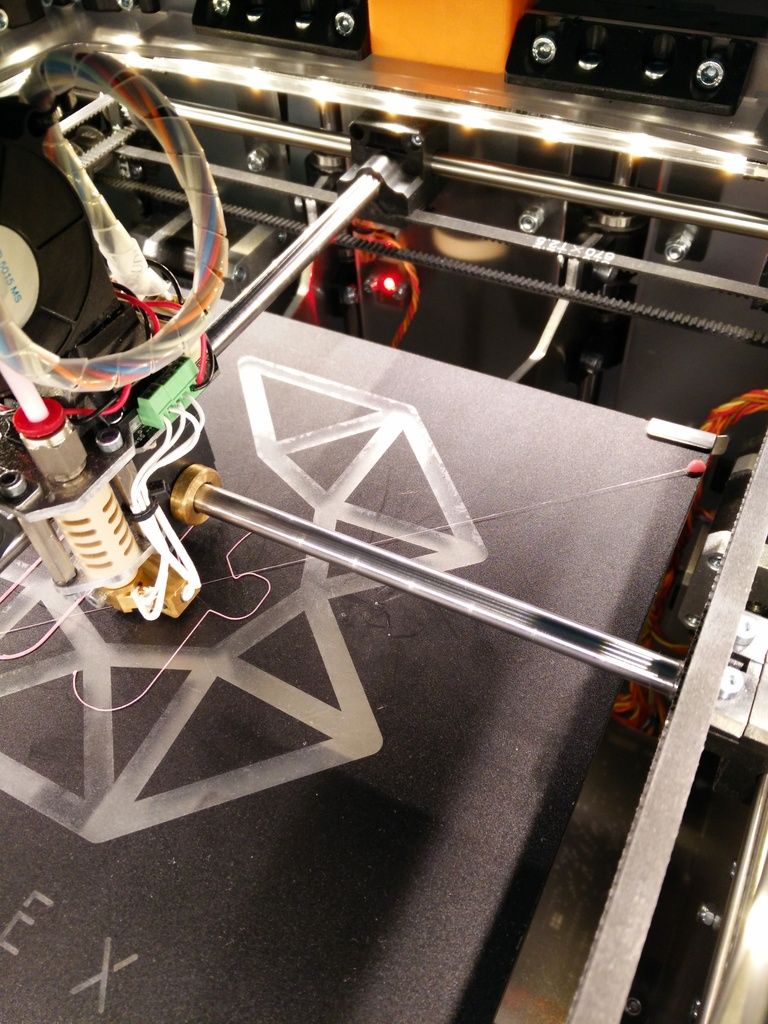

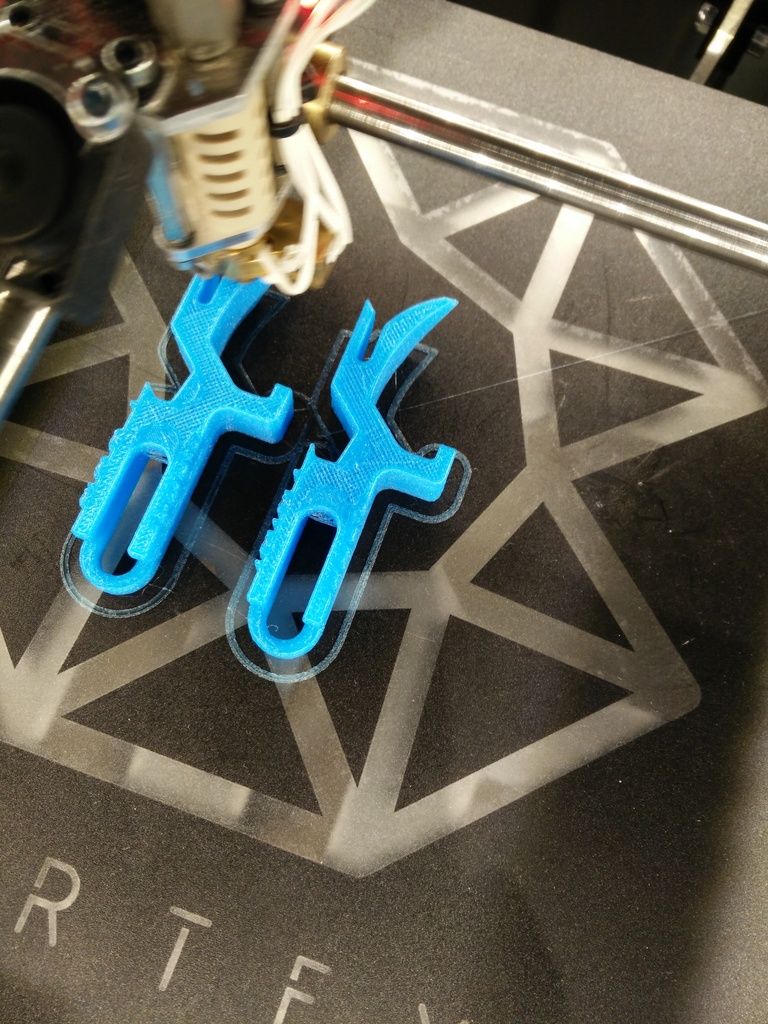

I also found some other problems, but more software related I think. It looks like the extruder doesn’t stop extruding when travelling. Tried 3mm retraction at 150mm/s, but it got even worse. It looks that sometimes when he travels he lays some lines over the object (picture).

I did a very small part at 0,1mm layer height, and the part paused a few seconds between every layer. What is that for? How do I turn it off?

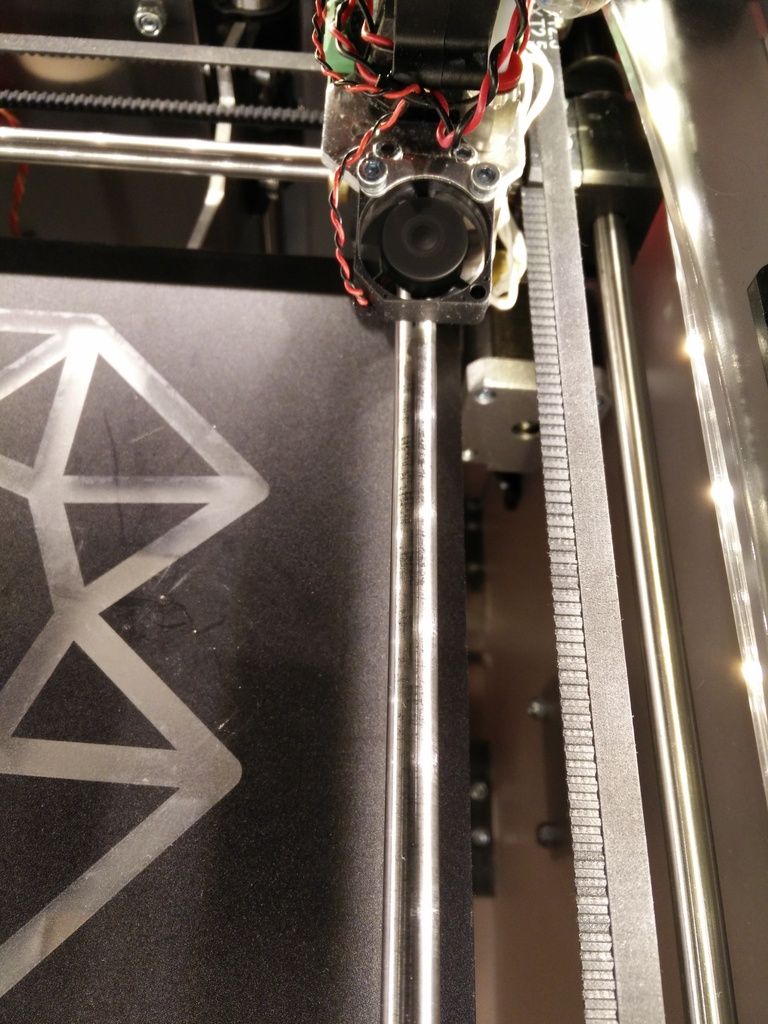

Last, I also found that my Y axis that goes thro the printhead, has some black stripes on it, while I ALWAYS worn gloves while touching them, the X axis has nothing!

Getting a bit unsure. I hope you can help me with all my problems, or with some of them. Tips that I don’t mention that I should have or do are welcome to!

Some pictures, if you need more, or some video’s, I can always make them. Printing settings tips are welcome to. Thanks allot in advance!

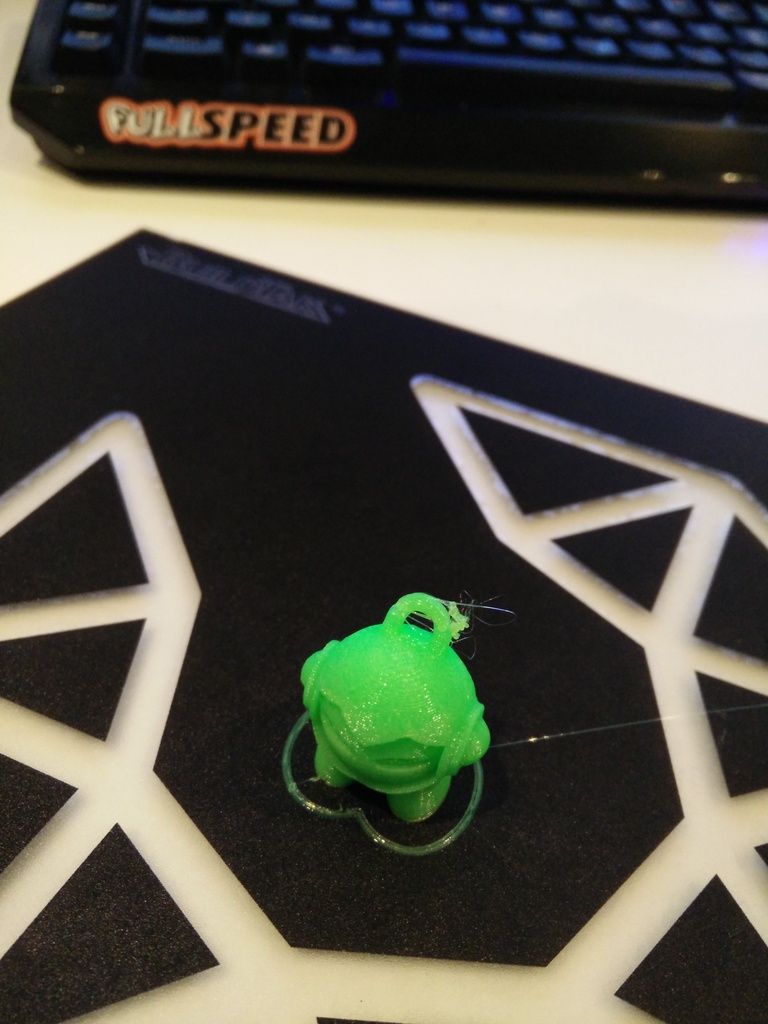

Here I think he still has some Z axis wobble? While I’m using the stabilizer? and the shaft and rod are more out of the coupler? Or is it due the vibrating of the bed?

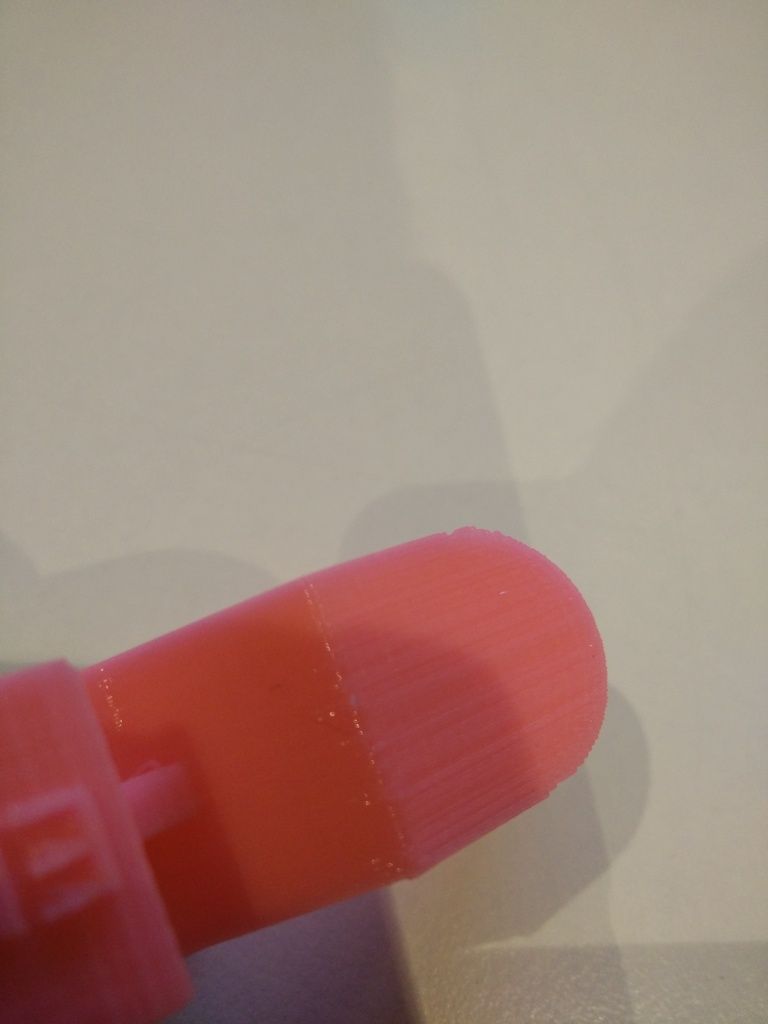

Here you can see the printer made a line, while he was travelling

Little video to, it looks like the pulleys are not perfectly aligned with the rods, you can also hear that the moving sound is different in certain spots, I think where the belts get more tension due to the not aligned pulleys…

I always worn gloves, and still do !!!

I always worn gloves, and still do !!!

I always worn gloves, and still do !!![/quote]Indeed. You can sand them with 1000 grit sandpaper (after removing the grease with a solvent). But it will come back (no stainless steel rods) and it doesn’t really matter if the rods are correctly oiled.

I always worn gloves, and still do !!![/quote]Indeed. You can sand them with 1000 grit sandpaper (after removing the grease with a solvent). But it will come back (no stainless steel rods) and it doesn’t really matter if the rods are correctly oiled.