When the LED is red, it indicates that either no filament is present or filament has run out. When this happens mid-print, the printer will automatically start a change filament procedure; the Vertex Delta will automatically pause the print job and will signal an alert. If you hear this alert, you will have to replace the filament spool with a new one, insert the filament into the extruder and the Vertex Delta will automatically start to load the new filament.

If you do nothing, the Vertex Delta will automatically start to cool down its nozzle after a few minutes as a safety measure. Yet, you are still able to replace the filament and restart the print job at any time (as long as you do not turn off the power).

Warning:

The Vertex Delta is only compatible with filament of 1.75mm diameter, yet some types of 1.75mm filament may have a slightly thinner diameter than others. This phenomenon may result in a filament runout detector malfunction. Why? Because the tactile filament runout detector may not register the slightly thinner filament and the Vertex Delta will think it has run out of filament.

Solution?

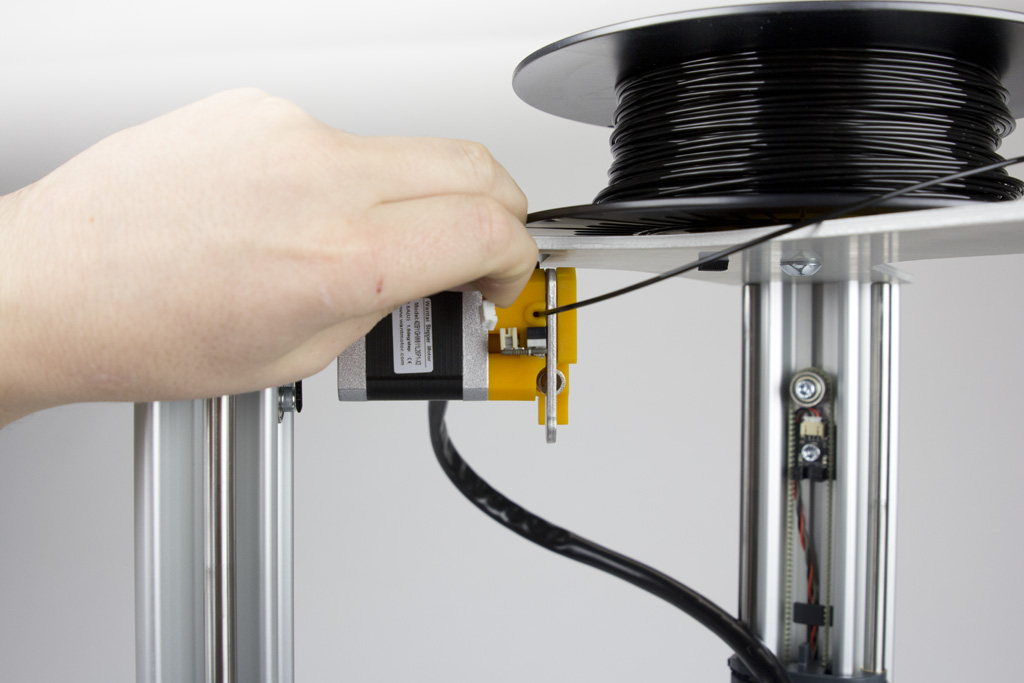

If this should occur, simply unplug the filament runout detector as shown in the picture below. But be aware that the filament runout detector will not function anymore. However, you will still be able to replace the filament mid print, as explained in the following chapter; 6. Changing filament while printing .

Regards,

Velleman Support