Got my K8800 for some days now. I had some issues that I could fix but I keep struggling with some weird printer behaviour:

When printing it unloads the filament and most of the times it loads it again and continues.

Different things can happen:

When the reload goes well:

- It resumes the print like nothing happened

- it resumes the print but the printhead doesn’t move, the nozzle gets buried in filament

- it resumes the print on a wrong height

- it resumes and unloads the filament again

When the reload fails

- the extruder servo keeps turning anticlockwise and the job has to be stopped

- the printer resumes the print without filament

- the printer resumes the job without filament on the wrong height

It happens with or without the filament sensor

I did do a restore failsafe and a EEPROM initialisation.

The issues happen after a fresh boot or after some successful prints

Any ideas?

I did search a lot for answers and tried a lot but to no avail.

Cheers

bonjour brechtt,

un probleme similaire, mais je n ai que le dechargement/rechargement en debut de cycle. apres c est impecable. je suis a l ecoute de solutions. a suivre

When the LED is red, it indicates that either no filament is present or filament has run out. When this happens mid-print, the printer will automatically start a change filament procedure; the Vertex Delta will automatically pause the print job and will signal an alert. If you hear this alert, you will have to replace the filament spool with a new one, insert the filament into the extruder and the Vertex Delta will automatically start to load the new filament.

If you do nothing, the Vertex Delta will automatically start to cool down its nozzle after a few minutes as a safety measure. Yet, you are still able to replace the filament and restart the print job at any time (as long as you do not turn off the power).

Warning:

The Vertex Delta is only compatible with filament of 1.75mm diameter, yet some types of 1.75mm filament may have a slightly thinner diameter than others. This phenomenon may result in a filament runout detector malfunction. Why? Because the tactile filament runout detector may not register the slightly thinner filament and the Vertex Delta will think it has run out of filament.

Solution?

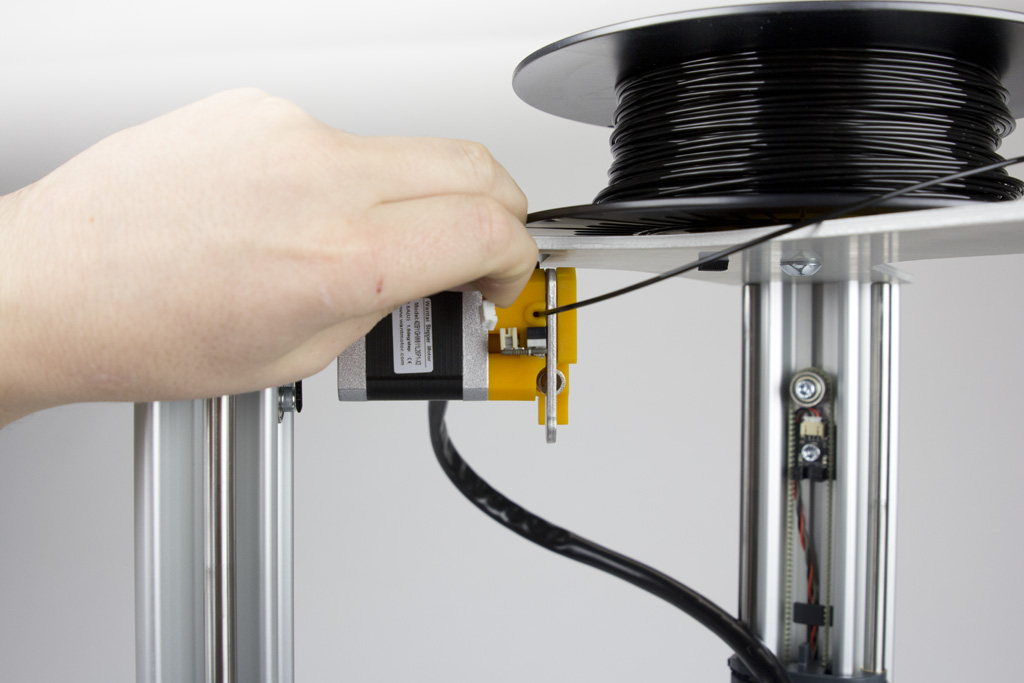

If this should occur, simply unplug the filament runout detector as shown in the picture below. But be aware that the filament runout detector will not function anymore. However, you will still be able to replace the filament mid print, as explained in the following chapter; 6. Changing filament while printing .

Regards,

Velleman Support

There was something wrong with the motherboard.

My printer went to the good hands of Velleman support and they fixed all of the issues.

Cheers

![]()