Hello, I have a Vertex nano K8600.

I have stringing problems concerning my impressions. So I try to fix this using retraction distance, speed of retraction, travel speed, temperature, Z hop but I cannot solve the problem …

For now, the best result had obtained with :

travel speed : 300 mm/s

T : 185 °C

distance retraction : 12 mm

speed retraction : 200 mm/s

Z hop : 0 mm

What do you think about these values ? Do you have any ideas/ suggestions to solve the problem ?

Can you post a picture of the failed print?

I noticed that when the filament is retracting, the print head makes a noise like “toc”. Is it possible that the distance retraction is too high ?

I don’t have that printer, but 12mm seems like a lot of retraction. I think I’ve typically used anywhere from zero to 4mm retraction on other printers.

What led you to set it so high?

Because I have the impression that the print quality was better gradually as the retraction distance is higher.

However I making new tests to confirm this.

So, I’ve made new test, and this is what I’ve obtained :

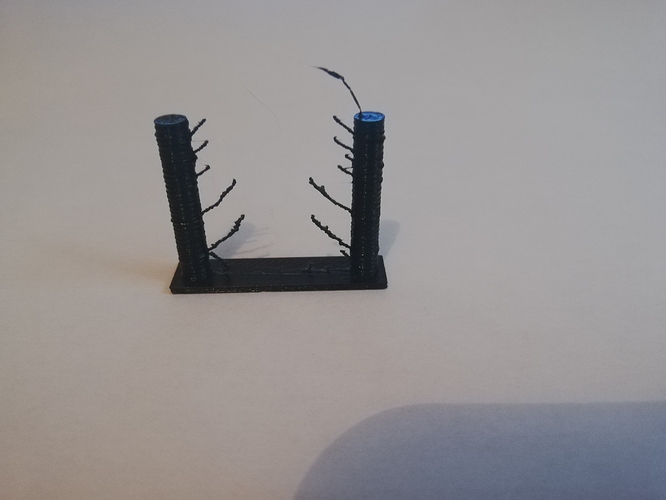

retraction distance, 0mm :

retraction distance, 3mm :

retraction distance, 6mm :

retraction distance, 9mm :

Now, the prints have failed for 6mm, 9mm retraction distance. With these distances, I heard a noise when filament is extruding from the print head ‘toc’.

Should I change another parameter to remove the stringing ?

What brand of filament are you using? Do you have another roll (a different brand, or color) that you could try it with?

I also wonder if 185C is a bit cool. I usually print PLA with an extruder temp of 190 - 195.

The brand is Velleman. I’ve tried with another color (yellow, always Velleman) but the result was the same.

I will try a print at 195.

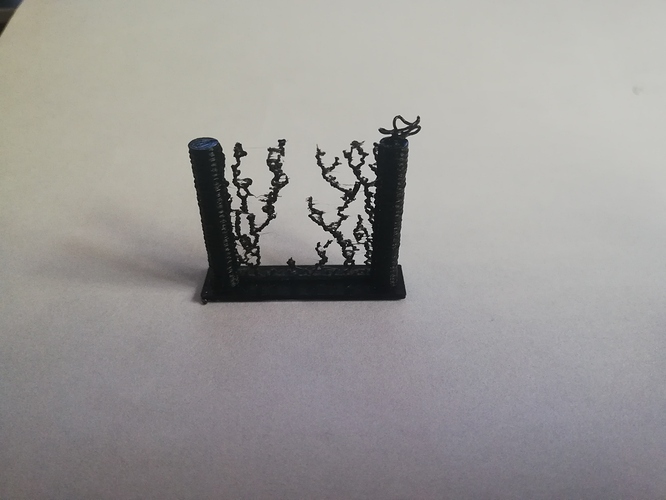

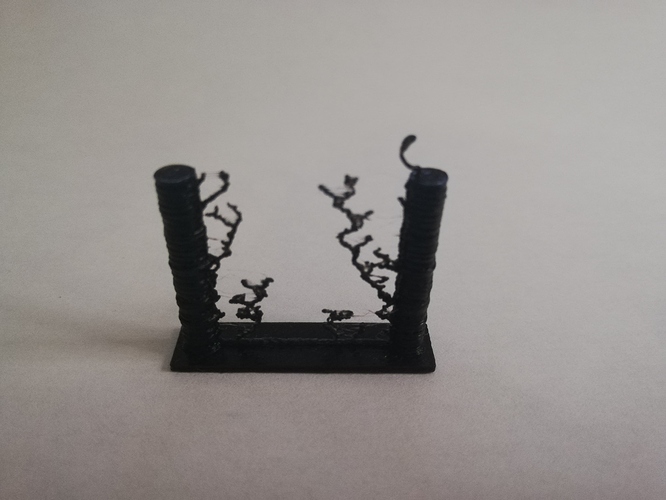

This is the result for a retraction distance of 3mm and 195°C for the print temperature :

That is odd.

Usually when I see stringing, the strigs are attached to the printed part. But your “strings” get progressively farther away from the printed part. That doesn’t look like what I usually think of as “stringing.”

Is it possible that the nozzle is damaged?

Is this part supposed to be two straight columns, or is there supposed to be some structure between them?

supposed to be straight columns…