When i’m printing my part. The printer Starts good but in the Middle of the print is he getting stuck or something. Dies someone know what I need to do?

Check out info about under extrusion on you-tube. Could be several causes.

My bed is perfectly leveled.

I tried multiple times and every time it is failing…

Give settings from (what do you use, slic3r?)

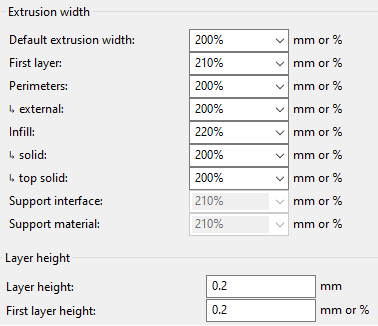

Remember that if you have 0.2 layer and nozzle diameter 0.4 then extrusion width must be 200%

It looks like you don’t have enough filament. The layer thickness is 100% and the value is adjusted to the diameter of the nozzle.

E.g

layer 0.1=100% / nozzle 0.4

(4x0.1 = 0.4 / 0.4) extrusion width = 400%

I use cure engine. But when I’m printing my filament Starts ticking. I thought my extrusion speed was to fast.

Have you changed or modified the firmware?

If yes,check the extruder step setting

Check the wheel on the extruder stepper has loosene

Is the hotend temperature correct (not from the display or the computer, but manually (with a thermometer)

E.T.C

Write something more.

I changed my Esteps/s from 200 to 148.7

My temperature is perfect.

I used the standard 0.15mm settings from cura engine.

Calculate the exact steps.

E= ( number of steps x microsteps x ratio ) / ( pi x diameter at the point of contact with the filament. )

Example

E = (200 * (8,16,32-choose one) * 1) / (3.14 * 22) = 3200 / 69.08 = 46,3231

(direct drive ratio =1)

E = (200 * (8,16,32-choose one) * 6,25) / (3.14 * 8,1) = 20000 / 25,43 = 786,4726 (gear extruder - We calculate the ratio of the number of teeth of a large circle to a small one for example 50/8 is 6,25)

This is very important to set correctly because in Cura or Slic3r it is the basic parameter for calculating the amount of filament

What do you meen with “diameter at the point of contact with the filament”.

What is the ratio with K8400?

It looks like the K8203 and K8400 are practically the same, In the photo you have calculated steps.( I had one K8203 and measured it )

I don’t know how it is in K8400 with microsteps 16 or 32 try settings for 16 and then you can see how it print.

Flow issues like that can also be caused by a clog in the nozzle. Clicking of the extruder motor can be caused by the shaft not turning easily, and a clog is a possible cause of that.