Hi @Wrong_Way,

thanks a lot, the bed is moving correctly.

Thanks for the hint, w.r.t the voltage. At this point they are at 0.42-0.43 range (it is a bit challenge to set it at exactly 0.425), but I’ll take this into consideration.

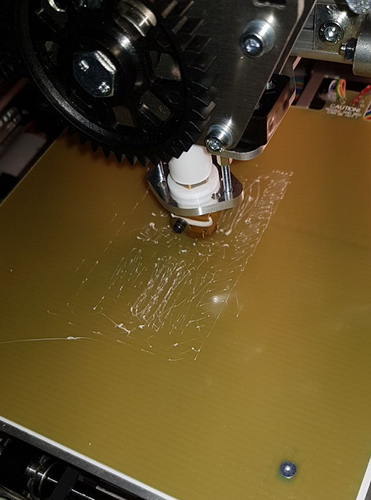

My key concern is the extruder now. I am trying to print the k8200 cover (as suggested by the manual), but the plastic is simply not going out. If I move the extruder (the big circle), the plastic starts going, but creates a mess (and stops flowing at some point).

Most probably I’ll need to post a new question on that… What do you think?