Hello Everybody.

I need some information. I want to improve mine K8200 and bought an E3d V6 Hotend 1.75 mm and a Titan Extruder for it.

I read the building manual which is available on E3d for the K8200 and there is mentioned that needs a 40 Ohm resistor for the Extra fan.

Okay but it doesn’t say from where does that extra fan gets Power, or where should I soldier it’s wires.

Does anybody have some information for me?

At the manual the problem starts at the Step number 35, here it is:

The other question is for the Extruder. I had a stock K8200 and how can I fine tune mine Titan Extruder for it? I will run it with the same Motor as it was given.

“The motor can then be wired into the supply input terminal.”

You can connect the fan wires directly to the power supply. The easiest way (as suggested in the instructions) is to unscrew the power connections at the green screw terminal into the controller board and insert the fan wires there before re-tightening the screws. So +15V goes to the fan red wire (through your 40 Ohm resistor) and black is connected to GND. The hot end fan will always be on whenever the printer is plugged in. The fan should blow air toward the hot end, but if it runs backwards you can either reverse the fan wires or flip the fan around.

I have not used the Titan extruder, I have only mounted E3Ds onto the K8203 extruder body. But if you are replacing the stock extruder with a direct drive, you will need to change the STEPS_PER_UNIT setting for the extruder motor in order to calibrate the filament feed rate. If my memory is correct, the 8203 uses 75 steps per mm of filament fed which may be a good first guess for calibrating your Titan if the documentation doesn’t tell you.

You will also need to update your Slicer settings to tell it that you are using 1.75mm filament instead of 3mm.

I don’t know if this answers your all questions, so please keep asking.

Thank you for your answer. You made my day way easier than excepted. Than maybe tomorrow I can install everything what I need and what I got for my printer. Just I question left in me. I didn’t install any resistor yet in my life and do i have to support it or it just hangs around.

And can I install a switch on to it? My Printer is almost always powerd on but it’s not running, but if I understand everything right that means the fan will be always on 24/7 and not only when I print?

Sure, you can put a switch in series with your resistor to turn the fan on manually. (Just don’t forget to turn it on when printing!)

I have my printer on a switchable plug strip to make it easier to power down the whole system. The printer can consume a lot of energy even in an idle state if left on 24/7. The extruder fan noise reminds me when I forget to turn the printer off.

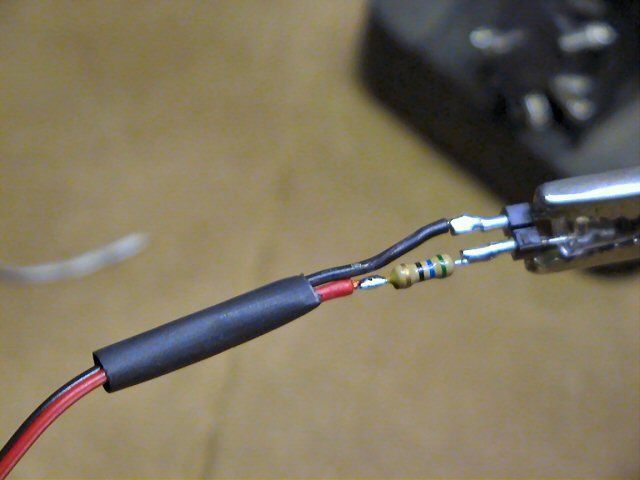

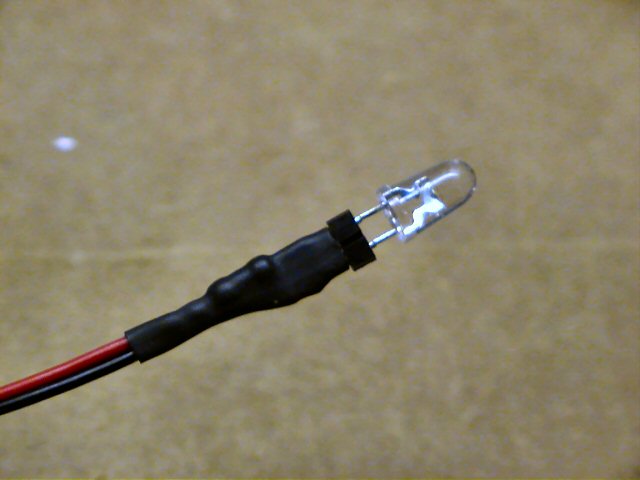

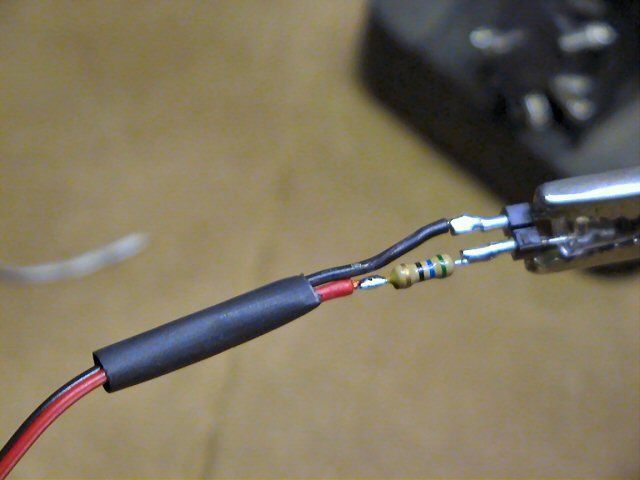

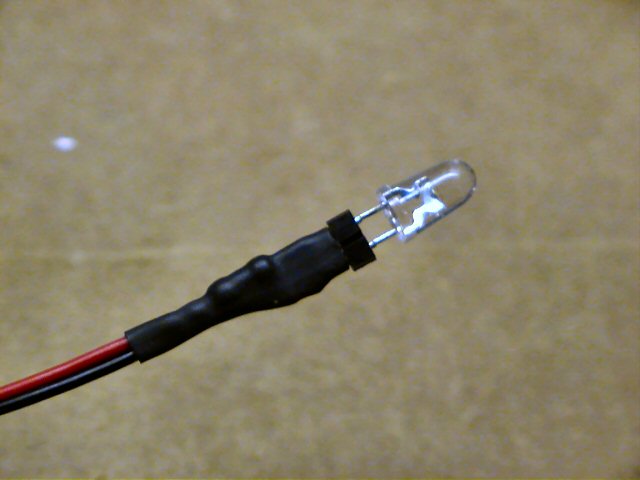

EDIT: I just noticed your question about the resistor. You will want to cover it completely to avoid electrical problems. The best way to do this is to slide a piece of heat-shrink tubing over the resistor, long enough to completely cover any bare wires. You can then add a second, larger piece of heat-shrink over both fan wires to give extra support to protect the resistor leads from breaking.

Here are some pictures of someone adding a resistor inline to current-protect an LED, but it might give you some ideas for how to insulate and protect the resistor in your fan wire: