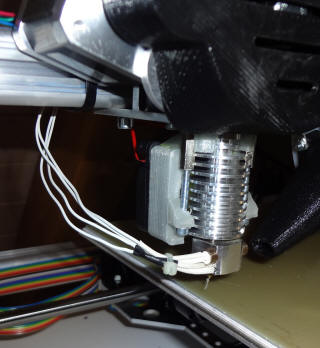

So I recently upgraded to a E3D V5 hotend and was having quite a bit of trouble getting things to print properly. I was dealing quite heavily with jamming, and by doing a little research online I found that a lot of people were having the same problems with PLA. Since I have only printed exclusively with PLA I decided I was going to try to find out if I could resolve the issue. The main issue that most were having is that the PLA would stick so easily to the bare metal extruder and cause jamming. One of these reasons was because the heat transfer from the heating block to the heat break and then into the active cooling area of the E3D hotend.

To counter this I decided to make a few model upgrades to some existing K8200/3Drag models on thingiverse.

The first was to upgrade kuraasu’s “E3D mount for K8200” [http://www.thingiverse.com/thing:221997] by changing it from a single 30mm fan mount to a dual 40mm fan mount. That model can be found here: http://www.thingiverse.com/thing:304919

I have found that the fins of the E3D hotend are cool to touch once I installed the two fans and mounted the hotend in. I can easily run the hotend at 190 for PLA without any issues it might fluctuate 3-4 degrees but overall it stays very constant.

I then wired the 2 40mm fans for the extruder mount right in with the cooling fan. There is some gcode a the end that makes the fans turn on at the beginning of the print to keep everything cool while heating up. I am not 100% sure on this because it means that the fan is running during the first layer, but I haven’t had any issues with it yet. Ideally I would like the active cooling fans to kick in while the printer is heating up and the material cooling fan to just run as default, if someone has a solution via hardware or firmware please feel free to share.

The 2nd model that I modified was simply because I now had a bigger mount now and my original fan print by eytec [https://www.thingiverse.com/thing:160252] wouldn’t fit. So I simply removed a section of the model [http://www.thingiverse.com/thing:305172]. It could be a little more as it doesn’t sit quite perfectly flush, but I didn’t want to take out too much of the air flow channel. The only other issue I had was the layer at 27.3mm prints a random solid layer in there, but it isn’t anything serious and I simply cut it out with a knife after the print was completed.

2 Other things that I did to make my life easier was to “season” the extruder which is simply running a little cooking oil through it, and then cleaning it with non oiled PLA to help with the sticking. That along with making sure that your tension on the hobbed gear is turned up.

Now onto software and settings. I use Cura almost exclusively now, I give up on Repetier Host once I saw the results of CURA. I still use Repetier for setup and maintenance functions just because it has more control in that regard, but for printing it is Cura 100%.

Ok, for my printer I am using the 0.25, 0.3, and 0.4mm nozzles from E3D. I have found that I more or less have to just change my nozzle size and the rest of the my settings stay the same from print to print with different nozzles.

Profile Settings are here: pastebin.com/T0NcFHhJ

Expert Config: i.imgur.com/pGPGSEp.png

Machine Settings: i.imgur.com/lIvzc2x.png (I have my heated bed off right now because the thermistor is broken and I am waiting on one in the mail)

start.gcode:

;Basic settings: Layer height: {layer_height} Walls: {wall_thickness} Fill: {fill_density}

;Print time: {print_time}

;Filament used: {filament_amount}m {filament_weight}g

;Filament cost: {filament_cost}

;M190 S50 ;Uncomment to add your own bed temperature line

M106 S255 ;Fan On

M109 S190 ;Uncomment to add your own temperature line

G28 ;home all axes

G90 ;absolute positioning

G21 ;set units to millimeters

G92 E0

G1

M82 ;use absolute distances for extrusion

end.gcode:

M104 S0 ;extruder heater off

M140 S0 ;heated bed heater off (if you have it)

G91 ;relative positioning

G1 E-1 F300 ;retract the filament a bit before lifting the nozzle, to release some of the pressure

G1 Z+0.5 E-5 X-20 Y-20 F{travel_speed} ;move Z up a bit and retract filament even more

G28 X0 Y0 ;move X/Y to min endstops, so the head is out of the way

M84 ;steppers off

G90 ;absolute positioning

I am sure that this gcode could be tweaked. I would like to have the hot end actually lift a little off the bed while heating up, but I find that it makes makes a nasty stepper motor noise when running with the default gcode that CURA ships with, so I removed it.

Anyways, any improvements to my findings are more than encouraged. I hope this helps out anybody struggling with the same issues.

Cheers, and happy Printing

Sam