Hi guys,

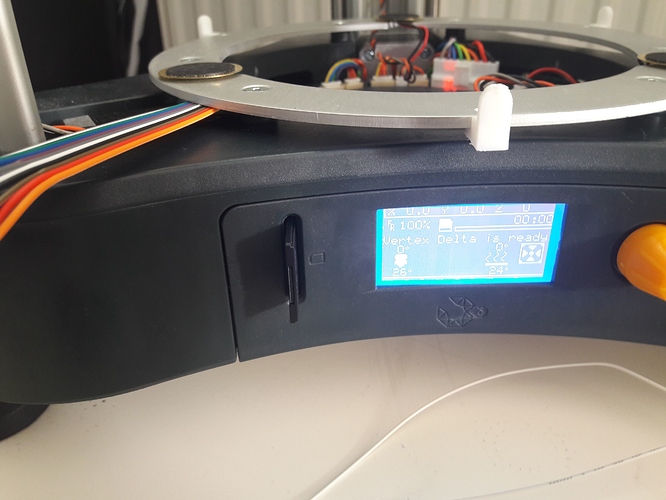

First of all: I really love the K8800, I got it at a really good price and the print results out of the box are pretty good. The overall approach that every part can be easily repaired or exchanged was exactly what I was looking for.

However, from my opinion the bed levelling with piezo sensors is from time to time a weak point. After some weeks my Buildtak is full of scratches, more or less useless in case you want a good first level. (no clue why but sometimes the nose is crushed into the bed and the printer doesn’t stop moving until I pull the plug, sensitivity changed in all directions).

Anyway that’s a different story – right now, I am trying to build a heat bed because especially with PETG I am facing from time to time some warping effects. PLA without buildtak is also tricky, tape (not the blue tape – this really doesn’t work at all in my case )+ hairspray etc. works most of the cases but its not a perfect solution.

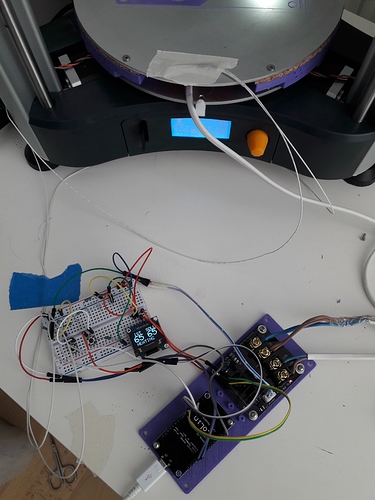

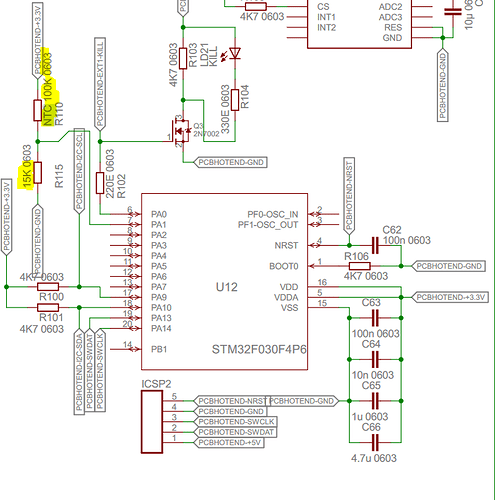

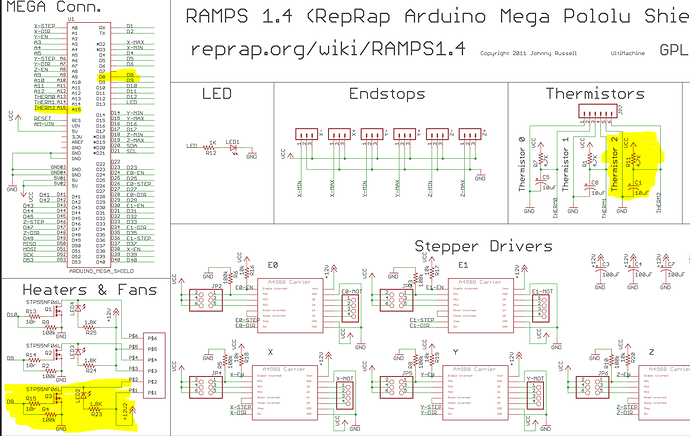

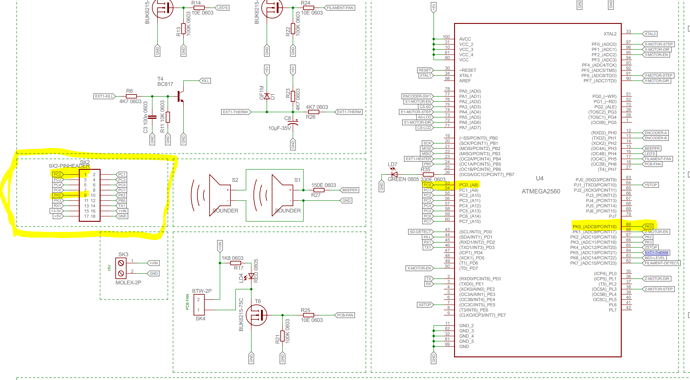

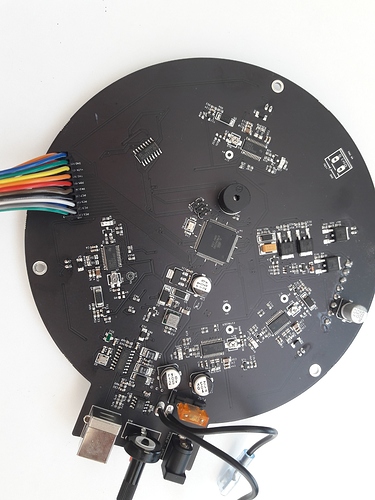

I bought a cheap MK3 round heat bed with ALU plate (~15€), build an Arduino based temperature control with a 100K NTC – no problem so far, maybe except for quite expensive 120W power supplies.

Obviously, now we are coming back to the piezo sensors. I couldn’t find information at which temperature they still can work but so far, I didn’t dare to place the heat bed directly on top of these at max temperature. I don’t plan to print ABS, so the max temperature I am looking at is 60-70 °C for PETG. I tested up to 30-35°C and it feels like the piezos getting more sensitive at higher temperature (no idea if this is true or not).

Can you tell me the Piezo specs?

I tested some ideas but its not yet working.

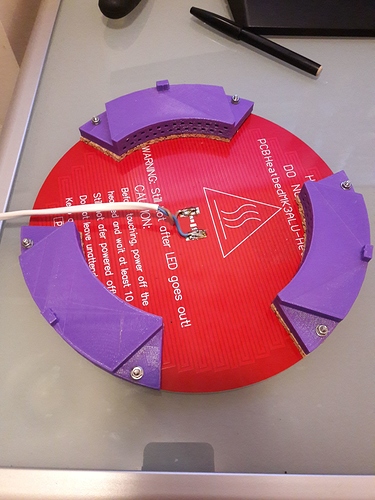

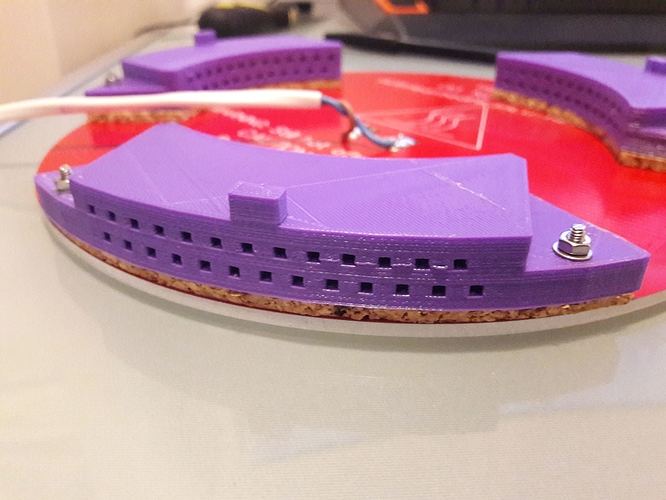

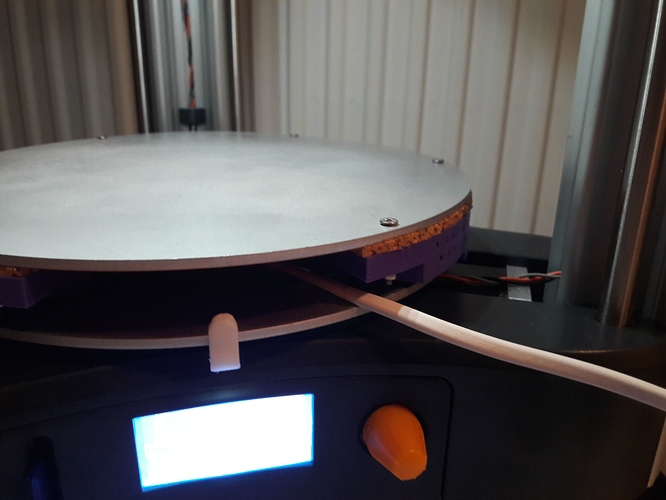

I have printed some place holders so that the heat bed is “flying” 2 cm above the piezos. Also the spacers change the diameter from 22cm (heat bed) to 21 cm of the piezo ring.

The Problem of such a solution is that the bumpers need to be tightly connected to the heatbed, otherwise the nose movement is not passed on to the piezos (and yes there are already scratched on the alu bed…). Its screwed together but when I start heating up the plate the connections got a bit lose. OK – I have printed the bumpers with PLA that might be very weak at 50°C – I have ordered some more temp resistant material (up to 130°C for my next try).

Any additional idea?

In case I cannot solve the piezo problem, I will remove the auto level function when using the heat bed. But I have one question here: How do I do a manual bed levelling? (maybe I am to stupid but I really don’t find this option in the menu)

Thanks and continue like that!

!

!