I have bought the vertex k8800. The leveling bed, is very slow, but after a few times it’s ok.

But the printing is very strange, in attachment the movie.

Please can you help me before i take a hammer;)

I can see a few mistakes.

The Buildtak goes on top of the glass not under it.

The print head is not turned the the right way (the fan should be facing the back if the machine)

Even though I can’t see the entire the cable going to the print head I don’t think you have it routed correctly.

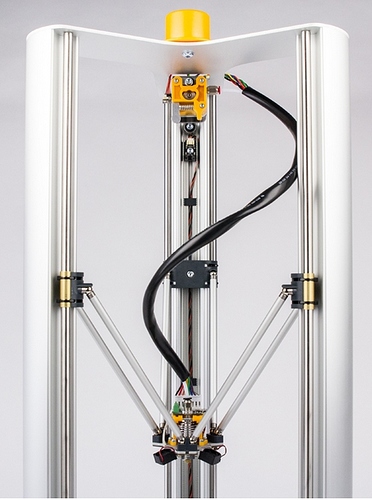

In the picture below look at the cable and how the print head is mounted

an you show with a arrow what is the Buildtak please.

Ok, i now what the Buildtak is, my college has build it wrong, i will fix it, and try it again.

The sticker glued on the glass made by a company named BuildTak. This sticker needs to be on top. yours is upside down. Did you run the calibration first and stored the settings?

Yes i have stored the calibration, but i didn’t hear the sound that confirm it.

Can I turn off the sound on the printer?

Other problem is, that when i start the printing the temperature on my computer is set on 195°c, and when the printing is starting the temperature is changing to 130°c.

Thanks for your help.

Maybe its the piezo sensitivity. too high or too low tune the potentiometer and repeat the calibration.

That is normal for the bed levelling it will change to your temperature setting when the levelling is finished.

It’s the printer of my school, so i will try it in 7 days, because we have vacation now.

I will come back later.

After you fix everything you will need to recalibrate it.

If you move it you will need to recalibrate it as well

Remember to keep it oiled.

Must i olied the magnetic balls?

Yes, with the recommended PTFE spray. But be careful that nothing of it gets on the BuildTak.

I have put the buildtak to the right position, recalibrate. Here is the movie of the calibration.

After that i try to make a figure, and that’s the result.

Philippe

https://youtu.be/jTtsH1H0Ees

https://youtu.be/IpEQP7sNK5E

https://youtu.be/FQVLFc1Nnkk

for me it looks like the BulidTak sticker somehow sticks to the clips that hold the plate in place. The plate should move free vertically. Use a sharp knife to cut away the parts of the sticker that are larger than the glass plate.

The BuildTak has a sticky side under the paper.

You need to peel it off then stick it to the glass then trim it.

Right now it’s interfering with the calibration.

See these instructions.

https://manuals.velleman.eu/article.php?id=767

I have cut the parts off the sticker from the side off the glass. And still the printer is crashing.

See movie. This when the printer is calibrating.

https://youtu.be/MeDeGGW3E9o

Check the calibration sensitivity in this chapter.

https://manuals.velleman.eu/article.php?id=771

Check the belts they maybe to tight?

Make sure the slides can easily go up and down.

Did you oil the sides and the magnetic balls and slides?